Prefabricated house

The subject of prefabricated architecture and in particular, prefabricated houses, are constantly being updated, designed and incorporating new capabilities in the face of technological innovations.

The development of new materials, modern techniques and the audacity of more than one construction designer has led to the development of modular housing construction in industrialized format, mainly represented in modern prefabricated or modular homes that some technicians identify as advanced construction technology for perfect homes.

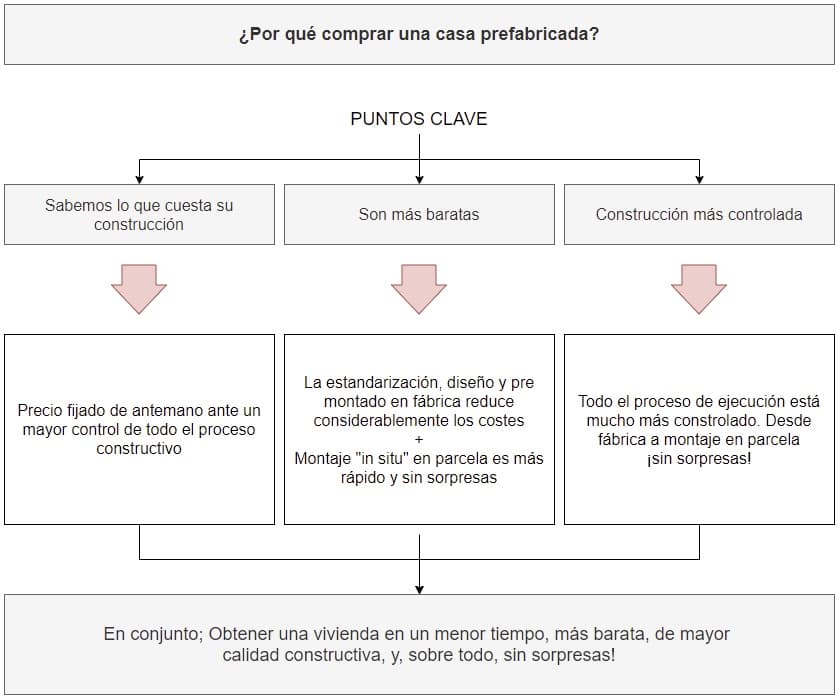

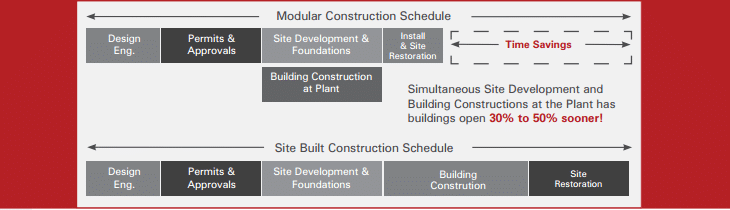

But… Why buy a prefabricated home? The most timely answer is in the following image

Prefabricated houses respond to the need for: lower or competitive prices, better finishes and design, construction quality, reduced execution times, high energy saving buildings, and, above all, to reduce the environmental impact.

So, the modern prefabricated house can be the right choice in many cases.

What is a prefabricated house

Prefabricated houses are dwellings built by standardized parts that have been built in a place different from its final location on plot. In short,“industrialized houses“.

Objectives! Modern housing requires skills and quick and effective solutions to meet certain customer needs with high performance and satisfactory results in less time, at a more affordable price and on a model of housing already tested in a rigorous and ideal process.

Modular constructions offer possibilities both in terms of rigorous manufacturing and on-site execution if they are carried out consistently in practice.

The real estate market when it comes to selling has a growing affinity towards prefabricated and energy efficient green homes in their modular designs that actually provide us with a modular type housing cheap compared to traditional construction.

We must remember that the market does not only offer the typical modular wooden house, we already find a long catalog of materials (aluminum – steel, all types of panels, concrete, polycarbonate, pvc, steel … etc) that thanks to technologies increasingly offer us more possibilities in resistance and qualities both in the walls, as in cover and the interiors of the same.

Modular housing concept

As we have already mentioned, a modern prefabricated house is one that is “built under a factory roof”, with modern construction machinery that in many cases works to the millimeter.

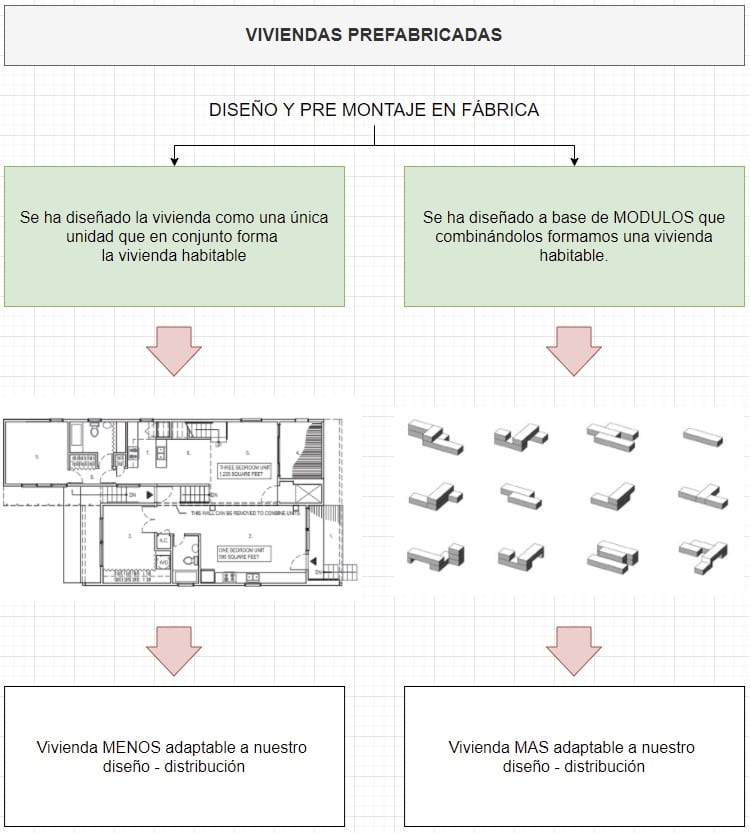

Prefabricated housing should not be confused with modular housing. A modular house is one whose initial design is made up of individual elements; bedroom, bathroom, kitchen, etc., which, as a whole, form a habitable dwelling.

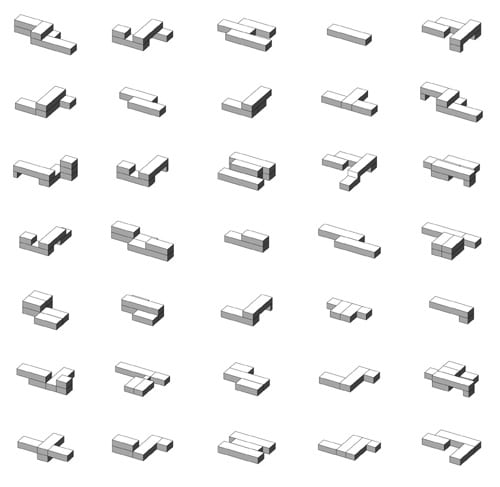

Leaving us from the typical standard of gabled housing, as examples of modular design we can identify the composition:

Undoubtedly, the “game” can generate a great variety of prefabricated modular house plans , although the reality is that simplicity is the cheapest way to buy a prefabricated property.

The production line of a house once finished, is what we can call “the container”, the housing module is transported in vehicles to the chosen site where the parts – containers will be assembled (Normally, on a sill – base or foundation already made of reinforced concrete) and thus the construction is completed in a short period of time.

We must remember that the modular home is not a mobile home, it is simply a home built off-site and that is why it differs mainly from the traditional man-made home.

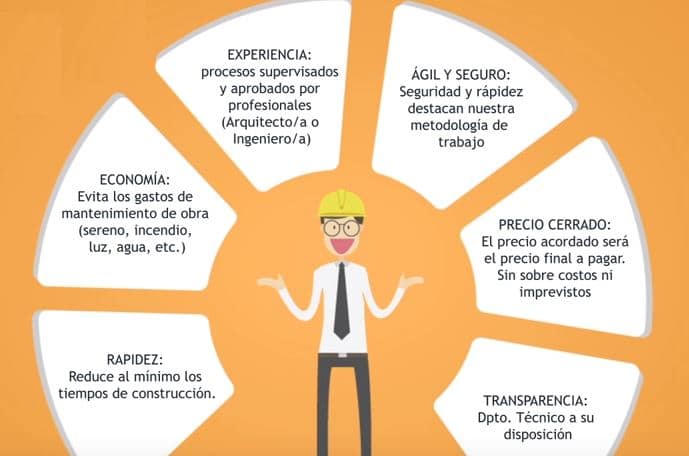

Normally the modern prefabricated house has multiple assemblies that make up the different rooms to inhabit. This system provides us with different advantages that we must analyze…

Advantages of prefabricated houses

1.- Control conditions

More control over the weather, quality control, improved supervision of the work, easier access to tools, and fewer deliveries of materials in time leads to lower cost and architectural quality of construction. These are tangible advantages that are difficult to manage on site.

2.- Environmental impacts

Cost reductions and less waste of materials, less water, dust and noise pollution, and less waste of energy in general, although prefabrication has an additional cost that must be quantified regarding transportation to the location.

3.- More compressed times

Changes can be made in the construction sequence, saving time and improving workflow, resulting in cost reduction.

4.- Less conflicts

When the house is assembled in the factory. There is a reduction of labor conflicts with the construction workers and a more programmed work.

5.- Improvement of materials

From the quality of the materials, both in staging and control, to reduction of storage space and a lower number of losses or misplacements.

6.- Security

Increased worker safety through reduced exposure to inclement weather, temperature extremes, and ongoing or hazardous operations; improved working conditions.

Disadvantages of prefabricated houses

- One of the most prominent drawbacks is the need to adopt to a pre-established design. We cannot always acquire the home of our dreams.

- Problems in the location of the property. It is necessary a series of circumstances to be able to transport in a suitable way the modules that conform the housing without considering the disbursement attending to the transport of the same ones that can increase in an important way the acquisition of the good.

- Given that the legislation does not adequately regulate this type of property there may be problems in the building permits or in the certificates of habitability since in many cases the prefabricated houses are acquired outside the Spanish territory, built according to other regulations and legislation. (Interesting to see the article of the expert report on building and the expert architect to understand a little more).

- Maintenance. Depending on the materials used in the project, it is necessary a rigorous maintenance of its different rooms.

- It is necessary to acquire a location, so the cost of the house should be added to the cost of the land.

- Depending on the climatological characteristics of the location, a prefabricated housing typology will be acquired. Building in the Mediterranean is not the same as building in Finland.

- The space of prefabricated ecological houses. The dimensions of prefabricated housesare usually smaller, standardized and pre-designed. When it is intended to acquire larger elements, the cost usually skyrockets due to the necessary adaptations to the customer’s requirements.

In this sense, both advantages and disadvantages of modular housing we already talked about in the article Container houses where we also inquired about the cost of the container and the different characteristics of the same as well as the construction methodology with a video example.

Prefabricated housing prices

We have made a small market study to see the prices of prefabricated houses for sale (We have not added the wooden houses that can be placed in a garden) We have only considered the prefabricated houses of concrete, metal or wood that contain a consistent and minimum conditions for living: (Prices shown excluding VAT)

| Prefabricated housing models | Surface area | Rooms – Bathrooms | Main material | Total price prefabricated house | Average m2 built |

| House 1 | 90 m2 Built | 3 Bedrooms – 2 Bathrooms | Concrete | 124000 Euros | 1377 Euros/m2c |

| House 2 | 220 m2 Built | 5 Bedrooms – 3 Bathrooms | Concrete | 248000 Euros | 1127 Euros/m2c |

| Dwelling 3 | 87 m2 Built | 2 Bedrooms – 2 Bathrooms | Wood | 37500 Euros | 431 Euros/m2c |

| House 4 | 269 m2 Built | 3 Bedrooms – 3 Bathrooms | Wood | 94300 Euros | 350 Euros/m2c |

| House 5 | 36 m2 Built | 1 Bedrooms – 1 Bathrooms | Metallic | 27500 Euros | 764 Euros/m2c |

| Dwelling 6 | 100 m2 Built | 3 Bedrooms – 1 Bathrooms | Metallic | 87500 Euros | 875 Euros/m2c |

| House 7 | 300 m2 Built | 5 Bedrooms – 3 Bathrooms | Metallic – Concrete | 320500 Euros | 1070 Euros/m2c |

| Dwelling 7 | 102 m2 Built | 2 Bedrooms – 1 Bathrooms | Concrete | 170000 Euros | 1650 Euros/m2c |

| Dwelling 8 | 82 m2 Built | 2 Bedrooms – 2 Bathrooms | Concrete | 140000 Euros | 1700 Euros/m2c |

| House 9 | 203 m2 Built | 4 Bedrooms – 3 Bathrooms | Concrete | 332000 Euros | 1600 Euros/m2c |

Things you should know about the price:

- There is a significant disparity between the offer that is marketed between different companies, even if we are talking about homes with the same construction material.

- The larger the property, the lower the price per square meter built.

- The prices indicated are always “from”. So we must be especially careful in the budgets that we acquire. Ask for very detailed budgets and if possible, with “turnkey”.

- The materials in which the house is built are usually prefabricated; wood, with metal containers or concrete. Wooden houses are the cheapest and concrete houses are the most expensive.

- Many times the price that is offered does not include; transport, assembly of the house, geotechnical study, project or few indications of the interior finishes, to give some examples.

- The transport is around 2000 to 3000 € (a house measures 90 square meters) and the assembly of the house, although it depends on the meters, is around 70 – 100 Euros per square meter built.

In our case we asked a colleague who is dedicated to the construction of prefabricated houses who told us approximate price per square meter of a finished house with everything included; with normal standards are between 1400 and 1500 € square meter built.

Always ask for detailed budgets and that indicate real cases of prefabricated houses already built.

From here on, ask in several companies and always ask for a detailed budget of the construction of the prefabricated house so that you can compare. By the way! Also ask for references of real houses already built.

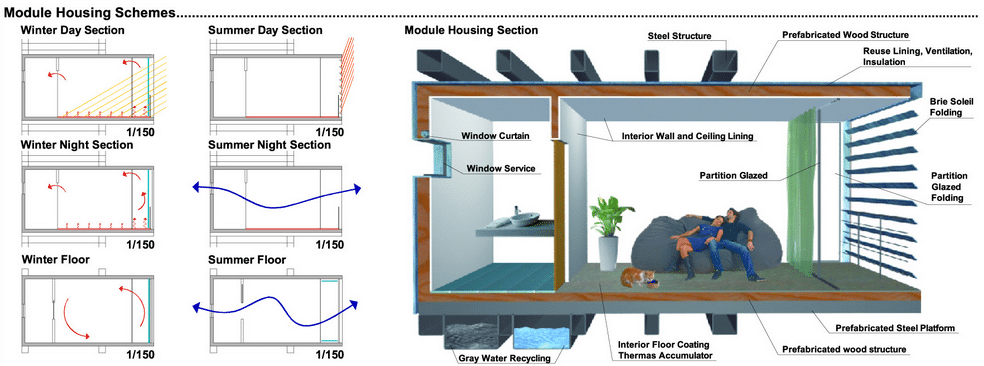

Efficient design of a prefabricated house and dwelling

It should be noted that the types of prefabricated houses that we can find in the market have had an exhaustive study on their energy and bioclimatic behavior. This is an advantage that makes it possible to save a significant amount of energy. Based on the “container” standard, we can identify their behavior in the following image:

Lots of efficiency and more, but…. are they really comfortable? Well, as an example I add the following video that seems to me to explain very well the essence of housing in a prefabricated house, besides being a real case:

In this sense, bioclimatism in design is recommended to see:

- House facade design (Bioclimatic design strategies).

- Architecture and form (How wind and sun affect)

- Introduction to sunlighting (Case study plus online tools)

Highly sustainable prefabricated house project

In this case we have to go to Australia to the company Archiblox committed to sculpting modular ecological houses that generate more energy than they consume, awarded with different prizes.

In Spain, there is hardly any industry of prefabricated ecological housing , moreover, people usually have a very vague generalized idea of this“modern architecture“, associating it rather to temporary and low quality constructions. Against this backdrop, it has a lot of merit that a Spanish company NOEM focused on a business of sustainable prefabricated houses with zero carbon footprint, obtains the European Entrepreneurship Award.

The example of modern prefabricated house

The shapes, the new technology and the different compositions of the plans in modular homes are shaping a modular aesthetic of great value and in some cases, even risky in its design. Modern prefabricated housing is here and this is an example of strong innovation. Invisible housing…

This wonderful house is built by DMAA. We must remember that the architectural modulation also goes into all types of construction; from buildings, industrial buildings or coworking offices to give some more examples.

How to build a prefabricated house

In this section, what we want is to carry manuals or PDF guides on how to build a prefabricated house step by step and have a perspective and intuit the works, plans, measurements and needs, tools, materials, concrete, wood … etc. .

The documentation represents the steps that we will need in the construction of the modules of the house as well as generic reports of the needs and objectives of modular architecture.

It must be taken into account that, the more parts of the dwelling are executed in factory, in a modular house, we will have a higher quality in the design both in the exterior – interior and in the air conditioning installations, doors, walls, finishes and qualities of materials, in the joints that form the envelope … etc…

The following video represents a building practically completed in the factory. An example of housing construction in 4 days:

Now it touches one completed on the ground, bearing in mind that the level of prefabrication can vary, from pieces of walls to complete parametersand likewise on the floor or roof. An example of housing construction in 7 days:

The manuals and guides we recommend are:

- The concept and history of modular homes. Modular housing construction and architecture HERE

- The current state of modular and lightweight housing as seen from an environmental point of view HERE

- Thesis – Prefabricated construction systems applicable to the construction of buildings HERE

- Modular buildings. A fast, versatile and reliable answer HERE

- Prefabricated construction design guide HERE (Excellent and extensive manual)

- Everything we need to know about wood in architecture and housing construction HERE

- Prefabrication and modulation in architecture from its economics HERE. (Very good economic report – English)

A problem that exists in terms of existing information and resources on the web is that prefabricated construction is undoubtedly derived from wood.

In this sense, since the article Architecture with wood already exposed more than 50 practical manuals and reports that expand the information in this regard, although, as a complement we provide some documents that we find of interest.

If you liked the article, share it!