Plastic recycling machine

Recycling is no longer an option, it is a necessity that we must assume, and here comes into play a resolved issue that has surprised us, we can make a homemade plastic recycling tool and with all the instructions!

From the Netherlands, designer Dave Hakkens proposes that we can assemble a plastic recycling machine ourselves with technology and materials that we can find anywhere and also using basic tools.

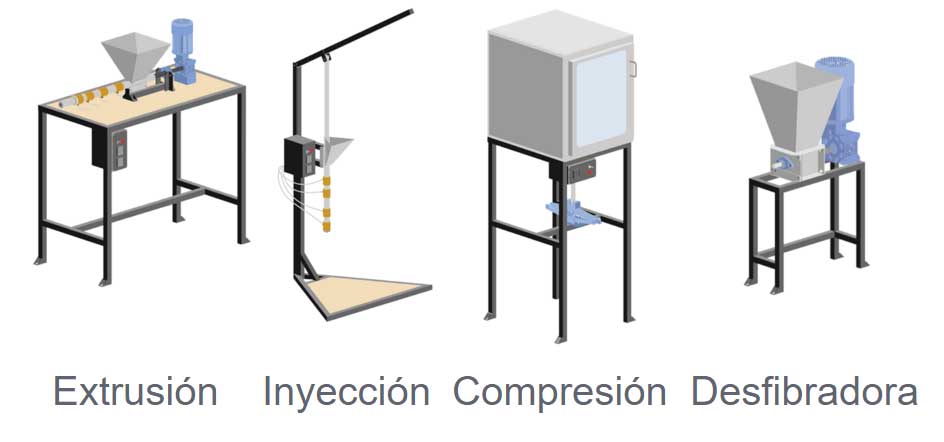

The designer did not want to miss a single detail of this unique proposition by setting up a web portal where it includes all the instructions – step by step – for the execution and assembly of the four recycling machines he proposes; A plastic shredder, an extruder, an injection molder, and another by compression on a mold.

He even adds the average price of the materials used per machine, the difficulty in building it, or the time it took to assemble it.

As we have seen in the video, the homemade machinery to reuse Pet plastic works perfectly and with detailed instructions and plans.

In the following image, we see the domestic plastic recycling devices that we can make (mainly PET plastics) for which we can download the plans:

The mechanisms proposed by Dave work on:

- Extrusion. To make a homemade plastic extruder that serves for; a continuous process where plastic flakes are inserted into the hopper and extruded into a plastic line. These lines can be used to make new materials like 3D printing filament, make granulated plastic, any type of mold, or use in multiple new and creative ways.

- Injection. Homemade plastic injector where plastic flakes are heated and injected into a mold. It is a relatively fast process, which is ideal for creating small objects repeatedly. We can make multiple molds adapted to our needs and create many objects with a really easy mechanism.

- Compression. Plastic is heated in the oven and slowly pressed into a mold. Very suitable for manufacturing larger and more solid objects, the oven itself is also a great mechanism for prototypes and plastic testing.

- Shredding. To make a domestic plastic shredder. Waste from different plastics is grated into flakes that will be used in other utensils to create new things. You can select the output size of these flakes by changing the sieve inside the utensil to create different processes and patterns.

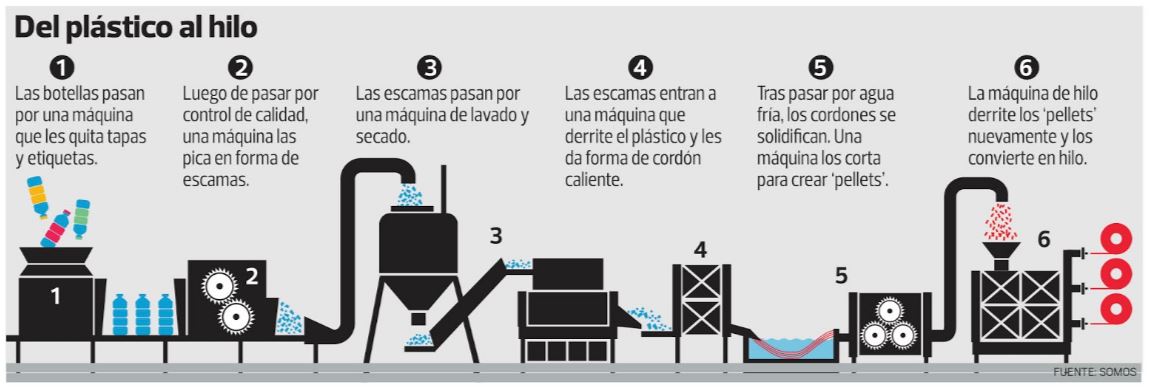

In reality, it would be to achieve something like the following image, but in a more artisanal and environmentally sustainable way, a homemade plastic recycler with a bit of crafting from home. The aim is to move from a more industrial process to a more manual one through simple assembly from our home.

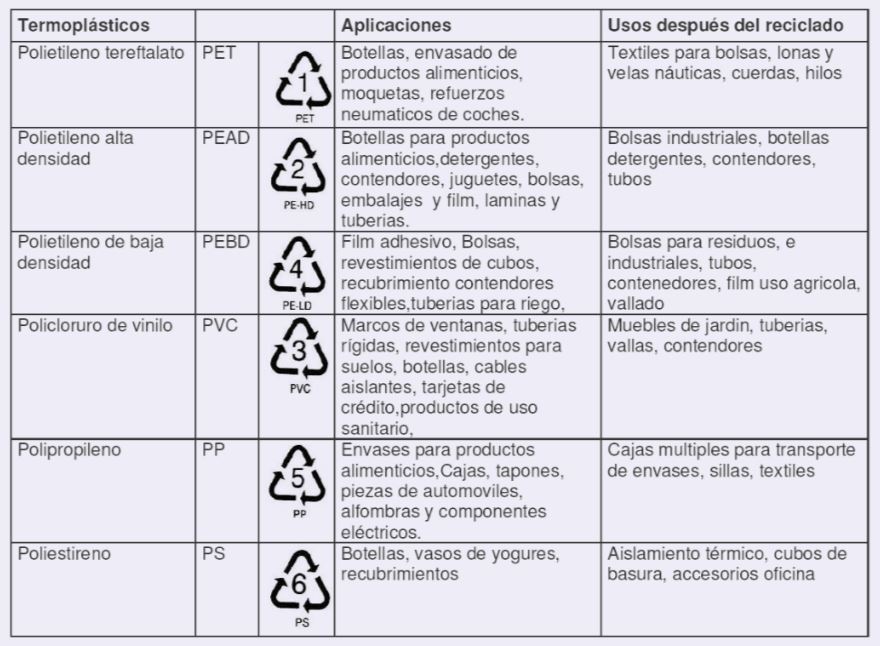

Another point we would like to remember since we are going to delve into PET recycling machinery, is how to take advantage of the materials we have at home and for this, we must be able to recognize the different labels. So we provide a summary infographic to clarify concepts.

In our article on recycling containers there is more information about labeling and plastic packaging. It can help you make your homemade plastic shredder.

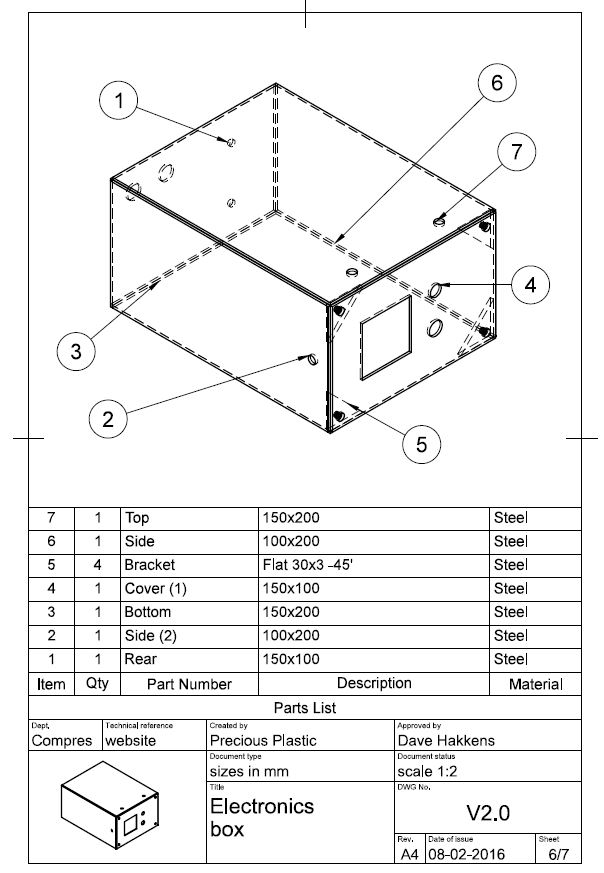

In the portal, we will find compressed download files with different PDFs with detailed information on the necessary tools and mechanism plans. Something like…

If we already saw in the article on creative recycling or in the one on recycled furniture made of wood with pallets where our imagination can go very far obtaining low-cost objects with good design.

The designer is committed to informing us in detail of the initiatives we can undertake with these plastic recycling machines from very detailed videos with ideas, instructions for the devices, necessary tools, plans, recycling tips …etc. That ultimately, form a new way to start living and educating ourselves, not only in DIY or recycling concepts and materials, but also in a new way to provide tangible benefits to the environment.

The previous plans and of all the machinery are downloaded from HERE (At the bottom of the page it indicates “Download KIT”)

Do you only want a machine to recycle plastic bottles?… Well, we have the Polyformer project similar to the previous one, but only intended to recycle plastic bottles to turn them into filament for 3D printers.

The Polyformer is another open-source project with all the CAD plans and documentation to create your own device to turn those pesky plastic bottles into something useful, in this case, filaments for 3D printers.

- All the relevant plans and documents for download from GitHub if you want to build it from scratch and at home.

- There is also the possibility to buy the assembly kit with the Polyformer parts that you can view from HERE at the end of the page is the information and assembly examples (the page takes a while to load).

? Note: We can also reuse more things. Learn from ideas to recycle clothes easily and from ecological alternatives to wrapping paper.

At the same time, the designer coined the concept of Phonebloks (modular phone) which is a mobile design made up of interchangeable modules with the aim of reducing electronic waste. We can learn more from the following video or on Wikipedia.

There are many initiatives to benefit recycling, but another that we find interesting is the simple yet effective device model that they have set up from Plasticbottlecutter to recycle plastic bottles – PET. Good but simple ideas that improve the environment!

With the Dave Hakkens initiative, recycling objects is no longer an obstacle if there is a desire to add value to society and the environment.

Articles of interest:

- Plastic made from fish skins and scales

- Conscious recycling

- Machinery in construction and works

- A robot to lay bricks

If you liked the article, share it!