Cross-Laminated Timber CLT)

Why is building execution changing? The culprit is a prefabricated construction material called CLT or cross-laminated timber composed of layers of glued and cross-laminated wood boards.

We are not talking about lightweight structures; they are CLT panels of precisely prefabricated wood that allow for the construction of both houses and sustainable buildings with extremely fast on-site assembly… Do you want to know more?

What is CLT wood?

Cross-laminated timber CLT are prefabricated panels of layers of sawn wood boards overlapped in perpendicular directions (90º) and bonded with structural adhesives.

By combining the framework of solid wood, the CLT panel gains strength, stability, and load-bearing capacity, making it ideal as structural elements for load-bearing walls, stairs, intermediate floors, or roofs!

We must remove the stigma of wood architecture as a “soft” or “flammable” material. CLT is an engineered wood product designed to withstand structural loads.

With CLT, we cross the boundary of using wood as a finishing material. Now… it is the skeleton of the building or house!

🟧 Fact: Although it seems like a new technology, CLT wood was developed in Austria and Germany in the 1990s.

Before continuing, I would like to provide⏩3 essential technical manuals from HERE (In spanish), The CLT Handbookon and Handbook Cross-Laminated Timber, CLT with construction details recently published by the UC Center for Wood Innovation (MINVU):

Uses of CLT wood

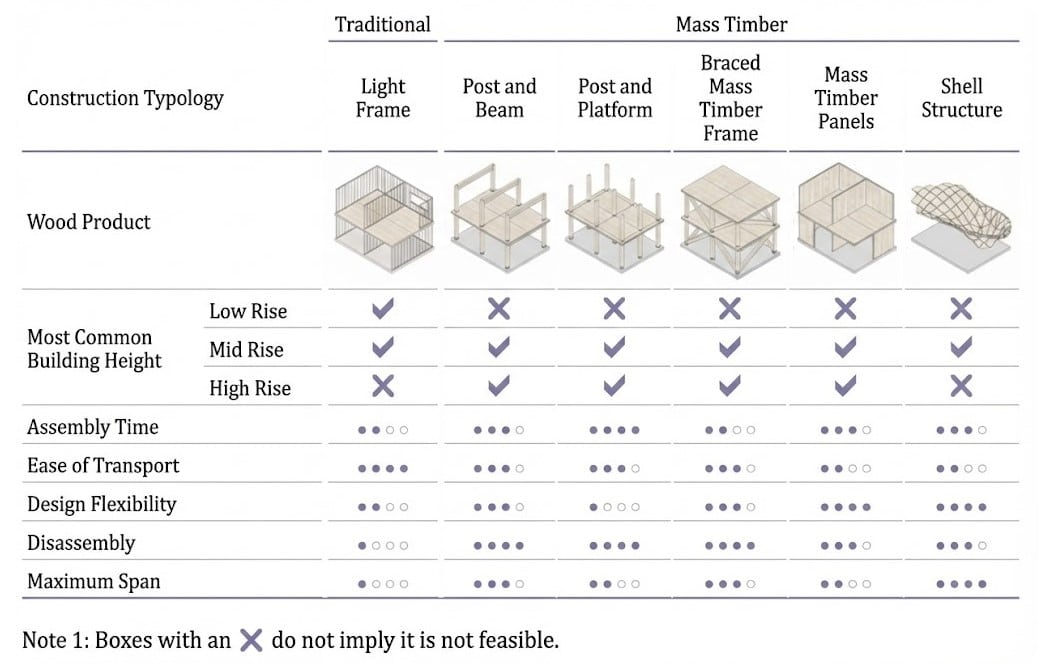

The emergence of cross-laminated wood boards has enabled “mass timber construction”. The use of CLT as a structural component in construction allows for load-bearing walls, intermediate floors, or roofs in buildings.

CLT has broken the mold of wood construction, allowing typologies that were previously the exclusive domain of steel and concrete

The applications of CLT panels are varied in construction typologies such as:

- Single-family housing: Used in wooden houses, it stands out for its industrial precision, fast assembly, or high insulation. It allows for aesthetic finishes with exposed wood.

- Multi-family buildings: Offers high profitability by being lighter, allowing for economical foundations or adding extra floors to existing buildings. Fast assembly accelerates the return on investment.

- Wooden skyscrapers: They are a reality thanks to detailed engineering and rigid cores. They require impeccable calculation to control settlement at height.

- Hybrid structures: Strategic combination with steel for large spans or with concrete to improve acoustics and thermal inertia.

- Public projects: Ideal for schools or public centers due to their reduced construction times (assembly during vacations) and psychological benefits (biophilic design)

A CLT building requires a multi-layer envelope that ensures comfort, tightness, breathability, and acoustic insulation

There is an interesting video about Designing with CLT, from concept to execution that is worth reviewing:

How a CLT panel is manufactured

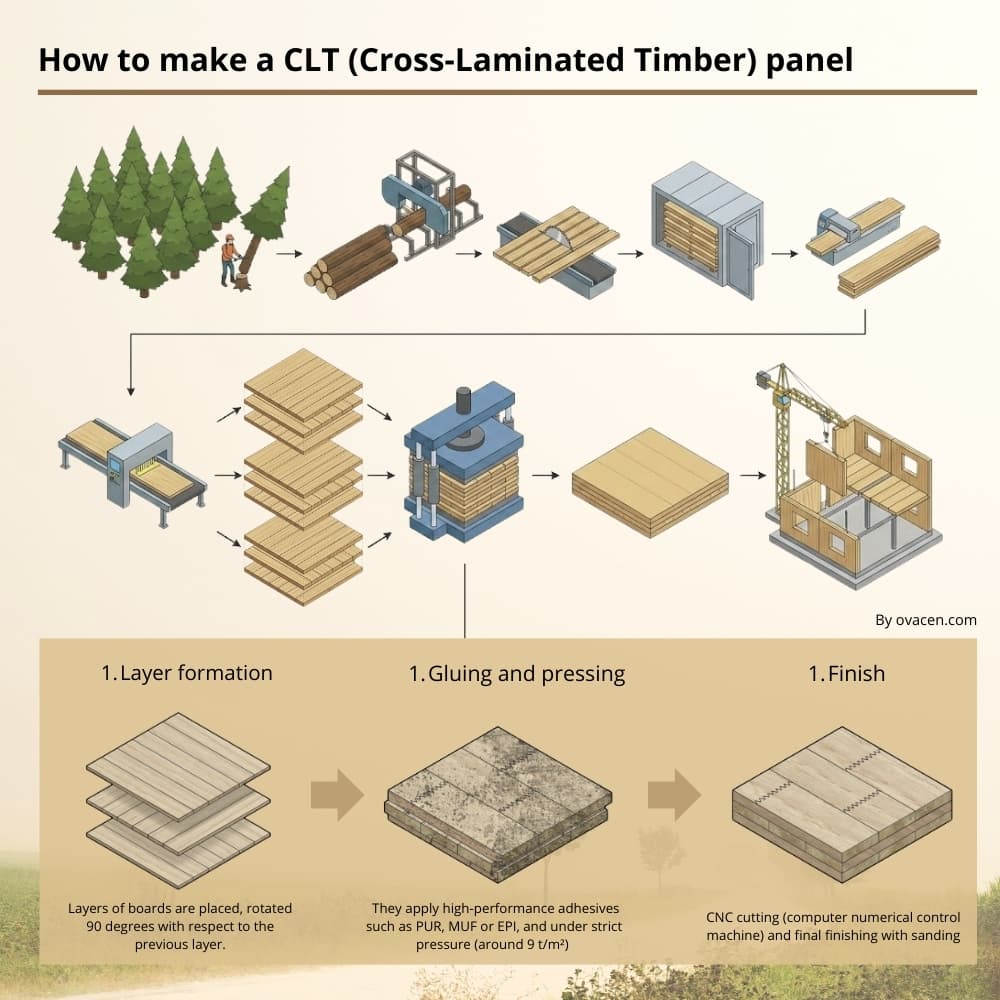

The magic of cross-laminated timber panels lies in their configuration. It is not a cut log; it is a technological panel. To understand its strength, the process is based on cross-lamination.

First, the CLT panel is technically classified as mass timber (mass timber), formed by joining smaller pieces of sawn or laminated wood from a log, not the entire piece of length.

The manufacturing system follows these steps:

- Selection of raw material: The boards are made of sawn wood (usually conifers like spruce or pine) and technically dried to reach a moisture content of 12% (± 2%).

- Preparation of sheets and alignment cutting: Each sheet is planed, cut to size, and carefully aligned.

- Cross-layering: Here is the secret. Layers of boards are placed rotated 90 degrees relative to the previous layer. Almost always in an odd number (3, 5, 7 layers) to ensure symmetrical balance.

- Structural gluing: High-performance adhesives like PUR, MUF, or EPI are applied under strict pressure (around 9 t/m²).

- CNC cutting: The “rough” panel goes through a numerically controlled machine that cuts openings for windows, doors, and installations with millimeter precision.

- Final finish: Once the piece is formed, it is refined by sanding to remove glue imperfections, cut, and obtain a smooth and uniform surface.

The result is a monolithic panel. By crossing the grains, the natural movements of the wood (shrinkage and expansion) are neutralized, achieving greatly improved dimensional stability.

Technical characteristics of CLT wood panel

1.- Physical and mechanical properties of CLT

Let’s forget about the calculation tables of conventional sawn wood. CLT plays in another league. Its mechanical properties allow for spans and heights unimaginable two decades ago.

Let’s break down its structural capabilities:

- Bidirectional strength: Thanks to the cross arrangement, the panel supports loads both in the longitudinal and transverse axes. It functions as a rigid plate.

- Lightness vs. Strength: CLT weighs approximately 5 times less than concrete, but maintains a very high structural load capacity. This drastically reduces the load on the foundation.

- Seismic behavior: Its high ductility and lightness make it an exceptional and innovative material for seismic zones. It dissipates the energy of movement much better than heavy rigid structures.

2.- Cross-laminated CLT dimensions

At this point, each manufacturer has its own dimensions in CLT boards where – in most cases – a standard surface at maximums stands out. Approximately we find:

- The number of layers: composed of 3, 5, 7, … even reaching 9 or 11.

- Thicknesses depend on the number of layers: normal range from 60 mm to 400 mm.

- Panel height normally maximum of 3 – 4 meters.

- Panel length normally maximum 12 – 14 meters.

🟧 Note: One of the major problems of CLT is not obtaining boards with large dimensions/surfaces, but being able to transport them to the site.

3. Thermal insulation and energy efficiency of CLT

What happens when you touch a concrete wall in winter? It’s freezing. Now touch a wooden one. The physical difference is thermal conductivity.

A pine CLT board has an experimental thermal conductivity of 0.12 W/m·K. It is immensely superior as an insulator: reinforced concrete has a value of 1.63 W/m·K (conducts heat 13 times faster) and steel reaches 58 W/m·K.

A CLT wood panel is 13 times more insulating than reinforced concrete, it’s that simple!

CLT provides thermal advantages in the building envelope:

- Thermal bridge break: Wood is a natural thermal insulator (its conductivity is very low compared to metals or concrete). It drastically reduces energy losses at joints and corners.

- Air tightness: CLT panels, being solid and well-taped at joints, create an effective barrier against unwanted air infiltration.

- Moderate thermal inertia: Although it has less mass than stone, CLT manages temperature peaks well, contributing to a stable indoor environment.

So, is insulation not necessary on exterior walls? Well, it is necessary. The technical recommendation is to install thermal insulation on the exterior side. An example of an exterior CLT panel:

By placing the insulation outside, the mass of the CLT is kept at a stable temperature close to the interior, preventing the panel from reaching the dew point.

4. Acoustic insulation

Here we must be clear. Wood is light, and in acoustics, mass usually rules! A bare CLT panel often does not meet the strictest acoustic regulations between dwellings on its own.

How do we solve this without losing the material’s advantages?

- Mass-Spring-Mass System: We do not rely solely on the CLT wall. We work with gypsum board and mineral wool linings. This combination dissipates sound waves much better than a heavy monolithic wall.

- Decoupling: It is vital to use elastic bands at the joints between floors and walls to prevent impact noise (footsteps, knocks) from traveling through the structure.

Metal connections (angles, screws) act as critical acoustic bridges

⚠️ Critical warning: Do not underestimate the impact noise on wooden floors. If you do not design the floor layers correctly (floating floor, anti-impact sheets) CLT requires “dressing” well acoustically!

5. Hygrothermal comfort

There is a subjective but measurable factor: the feeling of well-being. Wood is a hygroscopic material. Due to its porosity, it has the ability to regulate ambient humidity, absorbing excess and releasing it when the environment is dry.

Living or working in a CLT building improves indoor air quality and reduces static. It is what we call “biophilic design”: reconnecting humans with natural materials in their built environment.

🟧 Note: The adhesive between the wood layers acts as a vapor barrier. Adhesives like; PUR, MUF, or EPI, free of formaldehyde or with extremely low emissions.

6. Behavior of CLT wood panels in fire

Does cross-laminated CLT wood burn? Of course, but the technical response is surprising: it is incredibly fire-safe, often more so than bare steel.

The key concept is charring:

- Self-protection: When wood burns, it creates a surface layer of charcoal. It acts as a thermal insulator, protecting the inner core of the wood, which remains cool and structurally intact.

- It is predictable: We know exactly how fast the fire progresses (approx. 0.7 mm per minute). We can oversize the panel a few centimeters (“sacrificial thickness”) to ensure that, after 90 or 120 minutes of fire, enough healthy wood remains to support the building.

If the adhesive of the CLT panel does not withstand high temperatures, “delamination” occurs (falling of the charred layer), exposing fresh wood directly to the fire

A critical point in fire safety is the quality of the adhesive. If the adhesive does not withstand high temperatures, “delamination” occurs (falling of the charred layer), exposing fresh wood directly to the fire.

🟧 Note: You can consult the following technical guide on CLT in fire in the document of the American Wood Council HERE.

7.- Sustainability of CLT wood boards

If the structural strength of CLT convinces, its environmental behavior captivates. We are not talking about “being green,” it is building with coherence.

Let’s understand the concept of “Carbon Sequestration”:

- Natural storage: Trees absorb CO2 to grow. By transforming that tree into a CLT panel, the carbon is “trapped” in the building throughout its useful life.

- Substitution of intensive materials: For every cubic meter of CLT we use instead of concrete, we avoid approximately 1.1 tons of CO2 emissions to the atmosphere.

It is useless to use CLT if it comes from illegal logging. Environmental certifications like PEFC (Programme for the Endorsement of Forest Certification) and FSC (Forest Stewardship Council)

Main advantages of CLT

Cross-laminated wood (CLT – Cross Laminated Timber) has established itself as an efficient alternative to concrete and steel thanks to its properties. These are its main advantages:

1. Structural properties and dimensional stability

- Bidirectional strength: Its cross-layer configuration allows the panel to work as a bidirectional plate, offering high structural rigidity both in and out of its plane.

- Stability against moisture: The orthogonal arrangement of the layers restricts the natural movement of the wood, minimizing deformations, swelling, and shrinkage in response to hygrothermal changes.

- Technical uniformity: As an industrialized engineering product, it offers predictable and consistent mechanical properties, surpassing the natural variability of traditional solid wood.

- Lightweight structure: High load capacity with a fraction of the weight of concrete. CLT ranges between ~ 420 – 500 kg/m³ and concrete at ~2400 kg/m³.

2. Industrialization and construction efficiency

- High-precision prefabrication: The use of CNC technology allows for millimeter cuts in the factory, integrating openings for doors, windows, and installations before arriving at the site.

- Fast and dry construction: The assembly of large-format prefabricated panels reduces on-site execution times and minimizes waste/noise generation.

- Functional versatility: The CLT panel simultaneously acts as structure, enclosure, and division, simplifying the logistics chain and assembly systems.

3. Thermal performance and energy efficiency

- Superior insulation: It has low thermal conductivity (λ=0.12 W/m·K), far surpassing concrete (1.63 W/m·K) and steel (58 W/m·K).

- Air tightness: The massiveness of the panels and their adhesive layers function as an intelligent vapor barrier, eliminating unwanted infiltrations and improving comfort.

- Thermal inertia: Its thermal delay capacity (from 2.6 to 15.4 hours depending on thickness) optimizes energy consumption by mitigating exterior temperature peaks.

4. Sustainability and carbon footprint

- Decarbonization: As a renewable resource, CLT acts as a CO2 sink, presenting a negative or significantly lower carbon footprint compared to conventional materials.

- Forest certification: Its production promotes sustainable forest management, contributing to the circular economy in the construction sector.

🟧 Info: Our article on tools for viewing the solar shadow map of a house or buildings is interesting.

Main disadvantages of CLT (Challenges and limitations)

Although it is an innovative material, the use of CLT wood panels involves considering certain technical and maintenance limitations.

1. Hygrothermal vulnerability and durability

- Slow drying: Due to its volume and the adhesive lines acting as barriers, CLT dries much more slowly than sawn wood.

- Low biotic durability: Without proper treatment, wood is susceptible to attack by xylophagous fungi and insects.

- Impregnation difficulty: Post-manufacturing chemical treatment is difficult because the adhesive blocks deep penetration of preservatives.

2. Limitations in acoustic insulation

- Insufficient insulation at low frequencies: Despite appearing massive, the low density of wood prevents CLT from meeting high acoustic insulation standards (especially at low frequencies).

- Acoustic bridges in connections: Metal connections (angles, screws) act as critical acoustic bridges, transmitting vibrations more easily than the panels themselves.

3. Behavior and fire safety

- Risk of delamination: If heat-resistant adhesives are not used, charred layers can detach (delamination), exposing virgin wood to fire and accelerating the speed.

- Fuel load: If left exposed, CLT presents a considerable combustible surface that can contribute to the fire’s thermal load.

4. Specific structural challenges

- Rolling shear stress: The transverse layers have very low resistance to shear stress (approx. 0.7 MPa), as the fibers “roll” over each other.

- Sensitivity to concentrated loads: Detailed calculation is required at support points to avoid crushing the fibers of the transverse layers.

Moisture in CLT

The great “kryptonite” of the CLT panel is moisture. Good design and detailed engineering are its protective shield.

To prevent water from compromising the structural integrity of the wood, it is vital to implement at least four design strategies:

- Exterior protection: CLT requires an additional facade to protect it from the elements, as it cannot be exposed directly to the sun or rain.

- Insulation and tightness: Barriers must be placed between CLT and concrete to avoid direct contact and seal any air infiltration.

- Wet areas: In bathrooms and kitchens, CLT must be clad and sealed to prevent water from entering the panels.

- Hygrothermal control: A physical-environmental analysis must be conducted to prevent the formation of condensations that could affect the wood structure.

🟧 Note: If a panel gets wet accidentally (due to leakage or condensation), the priority is to allow it to dry quickly through ventilation. See article condensation moisture in houses.

Technical regulations for CLT

For the justification of CLT construction solutions under the Technical Building Code. UNE regulations:

- UNE-EN_16351 = 2021 – Timber structures. Cross-laminated wood. Consult from HERE.

- UNE-EN 1995-1-1:2016, Eurocode 5. Design of timber structures. Consult from HERE.

- UNE-EN 335:2013, Durability of wood and wood-based products. Consult from HERE.

Examples of houses and buildings constructed with cross-laminated CLT wood

The theory is all well and good, but… Where can we touch the material? Spain has gone from being a spectator to becoming a reference in southern Europe in construction with cross-laminated wood.

1. Wittywood

Located in Barcelona, this CLT project breaks the myth, a 100% wooden office building.

- Use: Offices (3,600 m²).

- Structural solution: Laminated wood beam system (GLT) and exposed CLT board floors. The building’s own weight is reduced, allowing for large spans and open spaces necessary for open space.

- Executed advantage: Industrialization drastically reduced execution times in a dense urban area, minimizing noise and neighborhood disturbances.

2. La Borda (Barcelona)

One of the most recognized buildings as examples of construction with CLT wood, both in awards and its contribution to cooperative architecture, is the La Borda building in Barcelona.

- Use: 28 Housing units in use transfer.

- Structure: It is built on a concrete ground floor. From there, 6 upper floors of cross-laminated panels (walls and floors) and auxiliary metal structure for the walkways.

- Passive design: The CLT panel acts as a natural hygrothermal regulator. The thermal inertia, although less than in concrete, is managed through cross ventilation and a central covered patio greenhouse type.

3.- Orueta Etxea House

The single-family home of Orueta Etxea has become an icon of modern architecture with CLT wood and has the Passivhaus certification in energy efficiency.

- Use: Residential single-family home (308 m2).

- Structure: Raw materials for its construction are from the house’s own area. Use of limestone in the foundation and CLT larch structural wood.

- Passive design: It meets Passivhaus standards. Wood occupies all interior finishes, both facades and roofs with this noble material.

Frequently asked questions about CLT wood

What does CLT mean in wood?

CLT means Cross Laminated Timber, in Spanish cross-laminated or laminated wood, formed by layers of glued and cross-laminated wood boards at 90% generating prefabricated panels that acquire strength, stability, and capacity to support both vertical and horizontal structural loads.

What is CLT?

It is a structural solid wood panel made with conifer boards (usually pine or spruce) glued in several cross layers to acquire strength, stability, and capacity to support structural loads.

Where can CLT be used?

It is used as a load-bearing structural element in walls, floors, and roofs, and allows for the construction of everything from single-family homes to multi-story buildings.

What is the thickness of CLT layers?

Each layer is usually between about 16 mm to 51 mm thick, depending on the manufacturer and project requirements. The finished CLT panel is usually between 60 mm to 400 mm.

How is CLT manufactured?

To manufacture CLT wood, layers of wood boards are glued perpendicularly to each other (at 90 degrees) and compressed using industrial presses to create large-format and resistant structural panels. Then they are cut with a numerically controlled machine (CNC) and finished with sanding refinement.

Maximum length of laminated wood beam?

In practice, laminated beams can be manufactured with lengths of up to 22 meters, but the normal length reaches a maximum of 12 to 14 meters conditioned by production and transportation.

What is the best structural wood?

There is no single “best”; in Europe, structural pine and spruce classified (for example C24) are widely used, and when more performance is required, technological products like glued laminated wood or CLT.

What are the 3 types of wood?

Simply put, they are usually grouped into: softwoods (conifers), hardwoods (deciduous), and engineered or derived products (laminated, boards, CLT, etc.).

Which is better, CLT wood or solid wood?

For large structural use, cross-laminated CLT wood is usually more stable, allows for greater spans, and has more homogeneous properties than solid wood; solid wood is simpler and more economical in small pieces.

What is the price of a CLT panel?

The price of a CLT panel depends on its length, thickness, type of wood, and adhesives used for its assembly. But, an approximate price of a CLT board with an interior OSB core of 46 mm thickness is around 83 Euros m2.