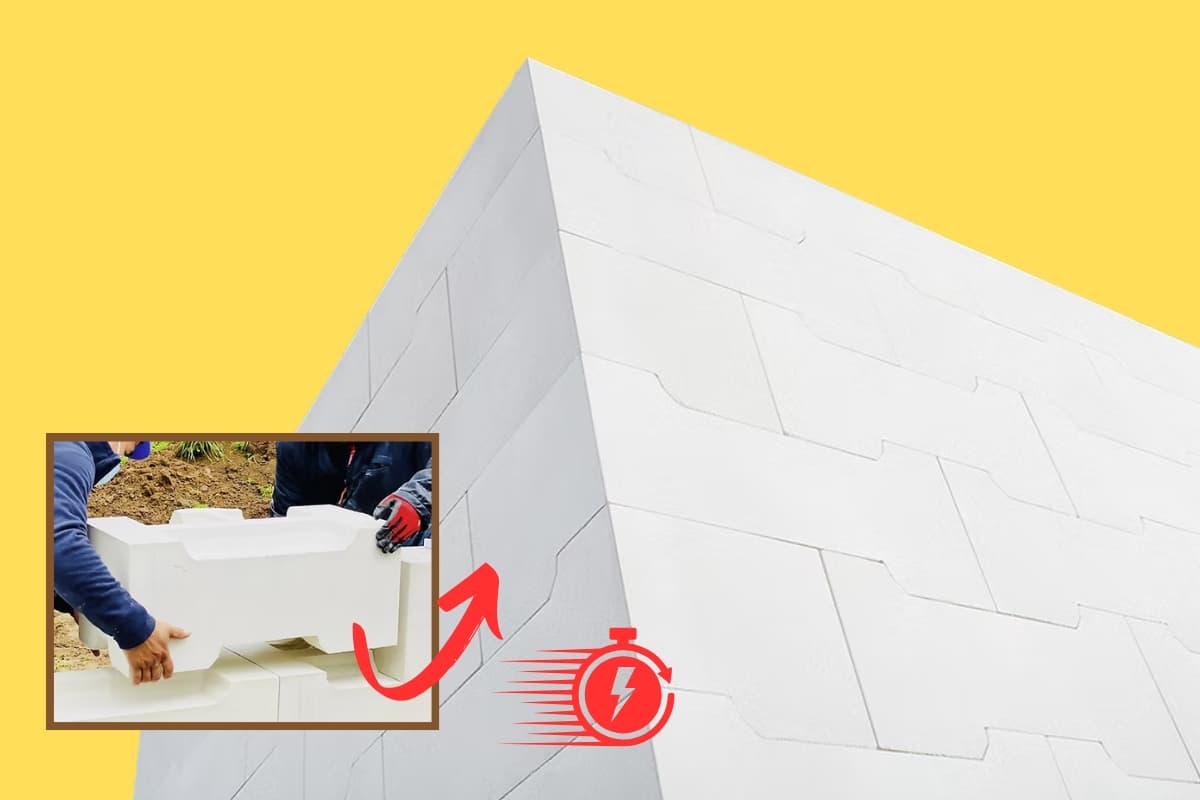

Building masonry walls quickly and without mortar

In my grandparents’ time, it was common to build walls with dry stone, without the use of mortar, just fitting piece by piece. Now, there are some startups that are betting on using the same concept but improving the technique and material.

Generally, they offer us concrete or ceramic blocks that fit like “Lego”… Which is great! But if you review the landscape of these companies, there is one that stands out, and it’s called System 3E (perlite blocks).

What makes System 3E blocks so different? Well, the pieces are made with perlite. A volcanic rock with thermal insulation, fireproof, lightweight, mineral, and chemically neutral properties—you can’t ask for more from the material!

If we add to this that the blocks fit with a “click-click” method and we don’t need bonding mortar, it starts to become a quite convincing material for modern construction.

In my opinion, we could almost compare it to the rise of construction with cellular concrete blocks due to its similarities in the capabilities of the material used. But… What features do the System 3E blocks present?

Technical characteristics of 3E blocks

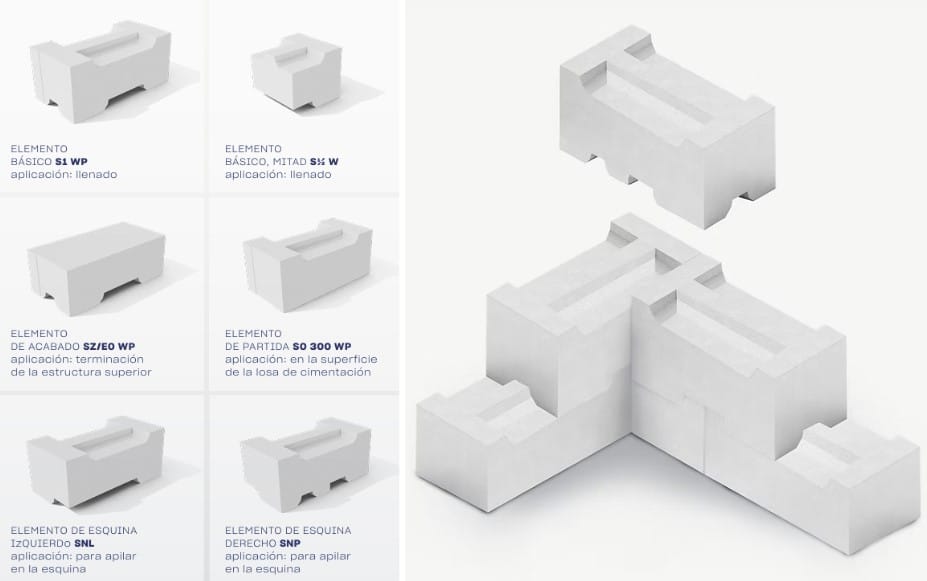

According to the documentation, they have 70 categorized element – perlite bricks -types according to their purpose. An example:

Both the manufacturing material and the precision of fit in the assembly of the blocks—mechanical connection that provides stability and resistance—are what confer uniqueness and advantage compared to other similar or traditional systems on the market.

The seismic resistance of the system is emphasized, mentioning tests that demonstrate its stability under significant loads and ground movements

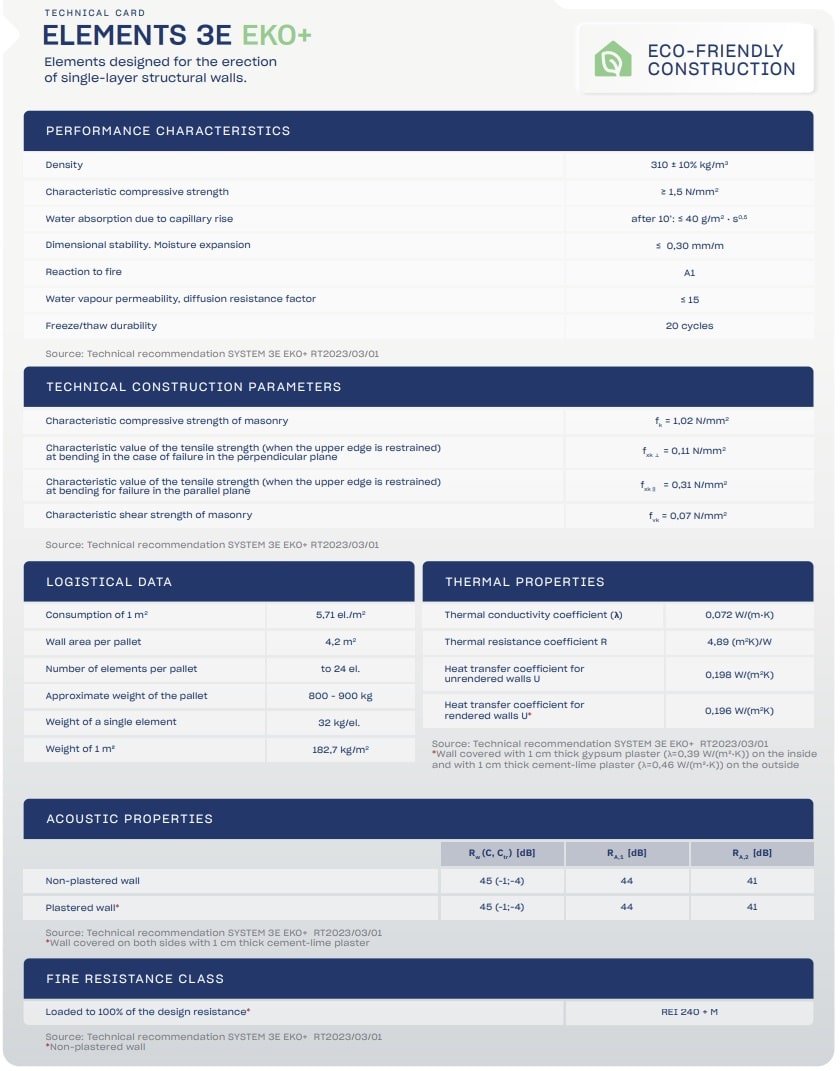

If we look at the technical characteristics of the following sheet, we can already observe that perlite (block material) has excellent properties:

Structural properties:

- Compressive strength: ≥ 1.5 N/mm².

- Flexural tensile strength: 0.11 N/mm² – 0.31 N/mm².

- Shear strength: 0.07 N/mm².

- Modulus of elasticity: 193 N/mm².

Thermal insulation properties:

- Perlite offers superior thermal insulation (λ = 0.072±0.003 W/m×K). It allows maintaining an optimal indoor temperature all year round, reducing the need for heating and air conditioning.

Volcanic perlite blocks that fit easily, insulate, and resist fire

Ecological and health properties:

- The high water vapor permeability prevents moisture and mold growth, benefiting health, especially for allergy sufferers and asthmatics. The production is energy-efficient, drastically reduces CO2 emissions and water consumption, and is a fully recyclable material.

Dimensions and modularity:

- The system primarily employs a modular design of 352 mm wide, 704 mm long, and 300 mm high. Most walls use 6 basic elements, with additional elements for complex designs. Apparent density: 310 ± 10% kg/m³.

Fire resistance:

- The elements are class A1 in reaction to fire. Load-bearing walls achieve a fire resistance classification of REI 240 + M under load.

Acoustic insulation:

- Walls of 35.2 cm offer good acoustic insulation: Rw (C, Ctr) = 45 (-1;-4) dB. Weighted acoustic insulation indices: RA,1 = 44 dB and RA,2 = 41 dB (both with and without plaster).

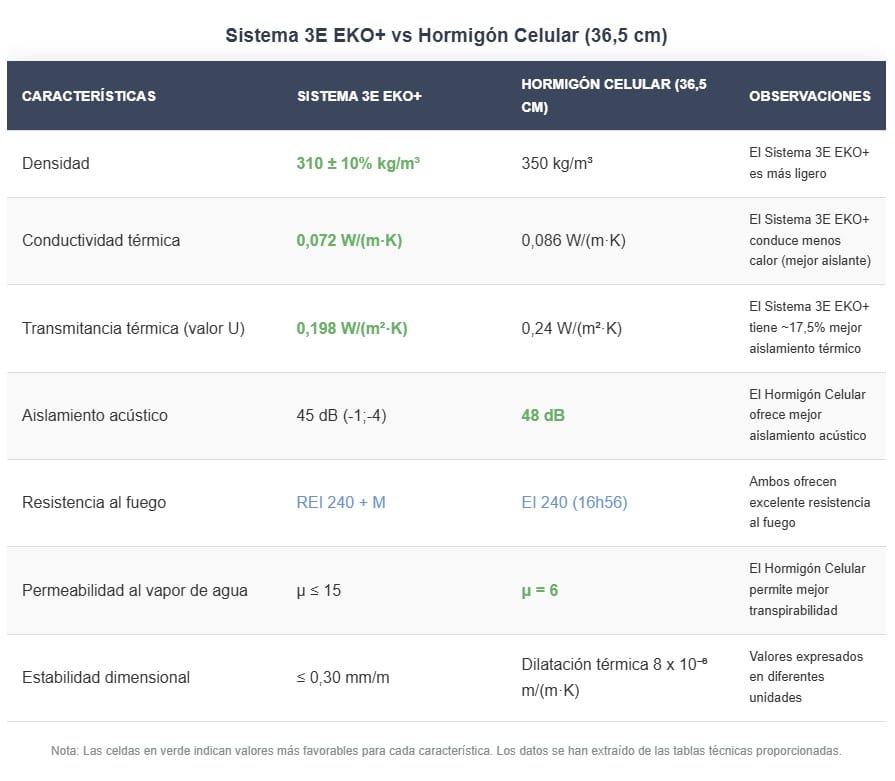

To have a more complete view and out of curiosity, I have compared these blocks (they are made of perlite) with Ytong brand cellular concrete blocks (they are mainly made of silica sand) with a width of 36.5 cm. According to the technical calculations they offer:

? Note: The above table is only a general comparison based on technical documentation from each manufacturer to better understand the capabilities of 3E technology compared to another material with similar behavior.

What advantages do 3E blocks offer

It is clear that the differentiation of this technology lies in not using any type of bonding mortar, therefore, the construction time of the wall is considerably reduced.

- Fire resistance: Tolerates high temperatures without breaking or exploding.

- Durability: Long-lasting material, resistant to decay and time.

- Thermal insulation: It has low thermal conductivity ( (λ) is 0.072 ± 0.003 W/m×K), meaning it is an excellent thermal insulation for both cold and heat.

The thermal insulation coefficient is very good compared to traditional concrete block and brick materials

- Quick assembly: Masonry execution is accelerated, and therefore, the completion of the work.

- Acoustic insulation: High sound absorption, improves comfort in buildings. A 35.2 cm wall has a simple weighted acoustic insulation index Rw (C, Ctr) of 45 (-1;-4) dB.

- Speed in construction: Due to the dimensions of the pieces, the reduction of other masonry operations speeds up construction on site.

- Clean and waste-free finishes: The finishes are clean and fine.

- Sustainable material: Its environmental impact is low, similar to that of wood.

- Water vapor permeability: Good behavior against water vapor diffusion resistance.

- Structural stability: Due to the anchoring system between pieces, considerable stability is provided in walls.

What disadvantages does building walls with the 3E system have

In the construction sector, there is no perfect material or system, so some disadvantages observed when using these blocks are:

- Unskilled labor: Masons are generally familiar with traditional construction methods. Although the system is simple, specific training is required for its correct application.

- Limitations in structural applications: Although the documentation indicates that they can be used for load-bearing walls, their structural performance has certain limitations compared to reinforced concrete.

- Dependence on a single supplier: This negatively affects aspects such as price, distribution, and material availability.

- Shipping costs: Another reality is that the manufacturer is in Poland, so there is an additional shipping cost for the material.

- Less construction flexibility: When deviating from the established standard, it is often necessary to resort to combinations with other traditional construction systems.

- The blocks are not so light: The standard block weighs 32 kilos. Obviously, in any execution of exterior walls, we find several masons, yet we will have to consider its weight.

Open Day at the SYSTEM 3E construction site in Dover, United Kingdom:

>⚠️ Although the company has an extensive catalog of construction details and technical documents indicating that they can be drilled or grooved for installation, I have not found anything related to cutting the blocks.

What is the construction process with 3E blocks like

This technology is suitable for a wide range of buildings, here we have to be clear that the elements are designed for masonry construction with interesting insulating qualities.

The process for wall execution would be:

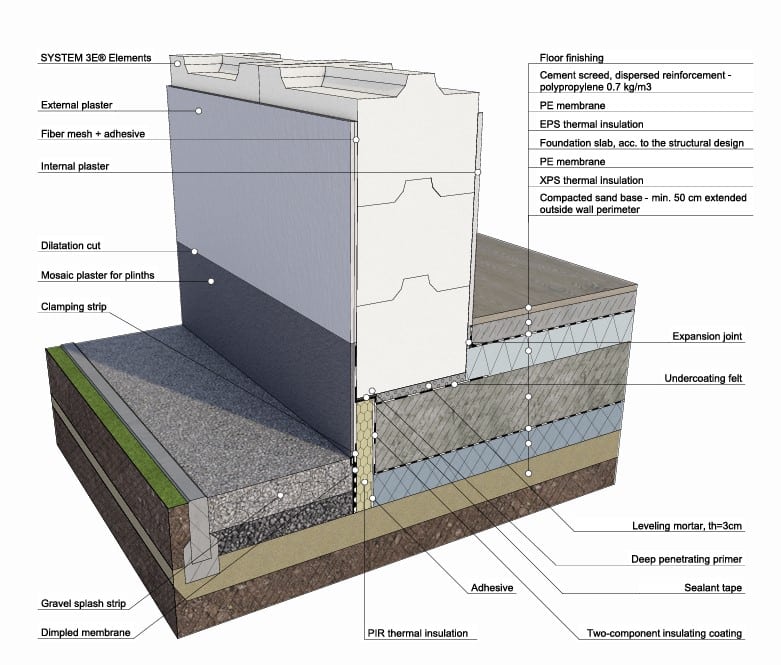

- Preparation of the foundations and application of a horizontal waterproofing layer and a mortar layer – between 10 and 30 mm – for the first row of elements.

- The placement of the elements begins at the corners, ensuring correct alignment and horizontality.

- The subsequent layers are placed without mortar, using the “click-click” system and adjusting with a rubber mallet (crucial to ensure that the elements are well fitted).

? Note: You can consult the guides and technical information on the execution of SYSTEM 3E from HERE.

To fix elements such as door and window frames, specific screw anchors are used (Rawlplug R-FF1, Hilti HRD, HUD, etc.)

Interior walls can be finished with a thin layer of plaster, lime, or plaster-cement, preferably preceded by a primer.

On the exterior, a layer of cement or cement-lime adhesive mortar reinforced with fiberglass mesh is applied, on which coatings or facade finishes can be applied.

Although it is a new technology and innovative material that we are not familiar with; seeing the energy performance, its execution method, and its speed in building walls, it might be a very interesting option for the construction sector.

If you liked the article, share it!

I would like to know the cost per foot. Possibly if I could get some information about this, or some stuff sent to me. I at 211 Hillcrest dr Story city Iowa 50248.

Hello. It’s best if you ask the company that sells the blocks directly; you can access their website at system3e.com