Weathering corten steel

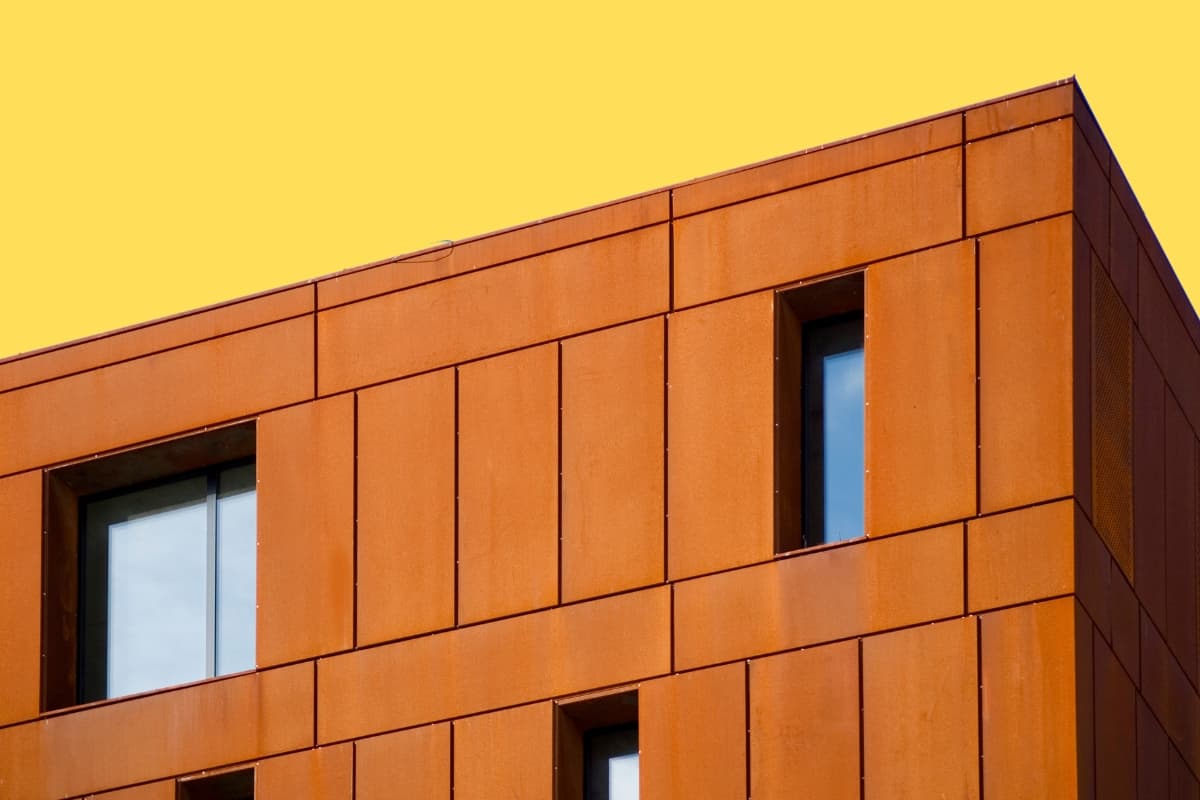

Corten steel (Cor-ten), also known as weathering steel, is a versatile material with a unique aesthetic used in modern architecture, urban furniture, or sculpture, to name a few examples.

Its unique and evolving appearance over time, along with its high resistance to corrosion, makes it an ideal choice for architectural projects seeking to stand out and endure.

We see it in impressive building and house facades, in elegant doors and corten steel windows that highlight the design of the most luxurious homes. However, it remains largely unknown… Would you like to learn more about this fascinating material?

What is corten steel?

Corten steel is a steel alloy with a specific chemical composition that gives it increased resistance to atmospheric corrosion. It is characterized by its dark reddish to orange-brown color with that distinctive rusty appearance, making it a weathering steel… But why?

This construction material consists of a mix of iron with small amounts mainly of copper, chromium, nickel, and phosphorus. This combination allows for self-protection through the formation of a protective patina – surface oxide layer – when exposed to the elements.

The surface oxidation of corten steel creates a waterproof oxide film, excellent for resisting weather conditions.

Characteristics of corten steel

Unlike conventional metals, which rust and weaken over time, weathering steel stands out for several unique characteristics:

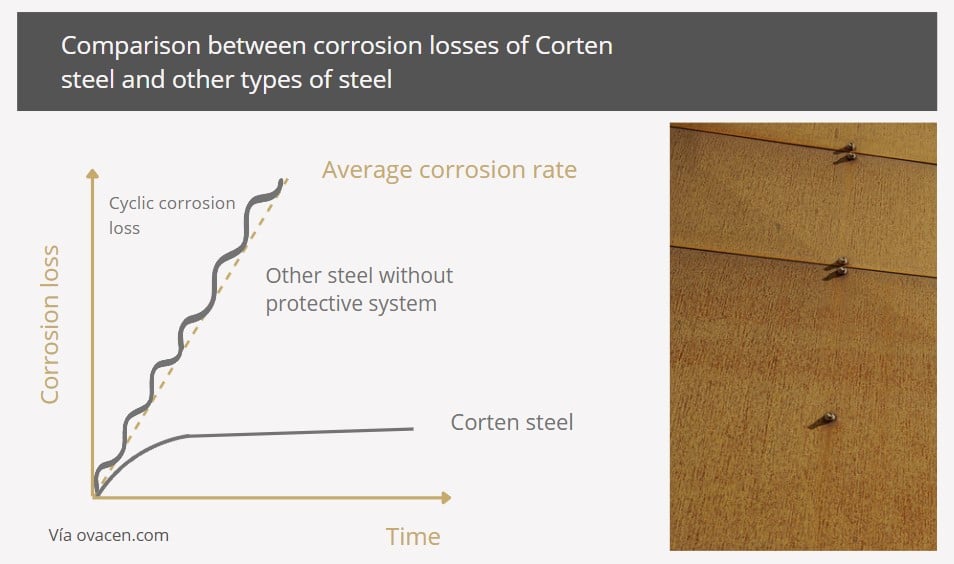

- Resistance to corrosion: The formation of a surface oxide layer protects the metal from further corrosion.

- Durability: It is extremely durable and can withstand harsh weather conditions, making it ideal for outdoor use!

- Low maintenance: It does not require painting or additional treatments. Long-term maintenance costs are reduced.

- Unique aesthetics: It offers a unique and modern look with a reddish color that blends well into any design, unlike PVC windows.

These are just a few highlights, but in reality, it has many fascinating properties…

Properties of weathering steel

One of the main properties of corten steel is its resistance to outdoor environments, durability, and sustainability, but there are also other noteworthy benefits:

| Properties of Weathering Steel | YES | NO |

|---|---|---|

| Weather-resistant | ✓ | |

| Fire-resistant | ✓ | |

| Bend-resistant | ✓ | |

| Scratch-resistant | ✓ | |

| Resistant to solvents and acids | ✓ | |

| Recyclable | ✓ | |

| Impact-resistant | ✓ | |

| Resistant to temperature changes | ✓ | |

| UV-resistant | ✓ | |

| Can be cut and modulated | ✓ | |

| Can receive coating | ✗ |

?Note: The standard regulating corten steel is the UNE-EN 10025-5. Hot-rolled products of structural steels. Part 5: Technical delivery conditions for structural steels with improved atmospheric corrosion resistance.

In terms of properties, the density of corten steel is relatively constant, around 7.85 g/cm³. It is typically sold in thicknesses ranging from 2 mm to 50 mm, and one cubic meter weighs approximately 7,850 kilograms.

The finished corten steel surface cannot receive a coating, such as being painted another color.

As a note, corten sheet – in English weathering steels – has a higher corrosion resistance than carbon steel but lower than stainless steel, which is directly more expensive. But… Are there different types of corten finishes?

Types of corten steel and uses

There are different types of corten steel, more defined by their resistance to atmospheric corrosion or special capabilities. The most common ones are CORTEN A, CORTEN B, and CORTEN P. To summarize, here is the following table on types and uses of corten steel:

| Type of corten steel | Composition | Characteristics | Main uses |

|---|---|---|---|

| Corten A (Grade A) | Chromium, nickel, copper | Good corrosion resistance | Facades, roofing, decoration, sculptures |

| Corten B (Grade B) | Chromium, nickel, copper, manganese | Higher tensile strength and rupture resistance | Structures, bridges, ships |

| Corten P (Grade P) | Chromium, nickel, copper, phosphorus | More adherent and strong oxide layer | Marine or aggressive industrial environments |

? Note: Besides the main classes of corten steel, there are other variations with different compositions and treatments: for low temperatures, with titanium, with copper, hot-rolled, forged, electro-galvanized.

It is a very versatile material, used in architectural projects (facades, walls, carpentry), urban furniture, decoration, in railings, fences, profiles, in glazing of enclosures, locksmithing, bridges and structures, artworks, etc. It has many uses!

To use it effectively, we need to understand how oxidation – patina – occurs and what happens over time.

Evolution of the patina and color

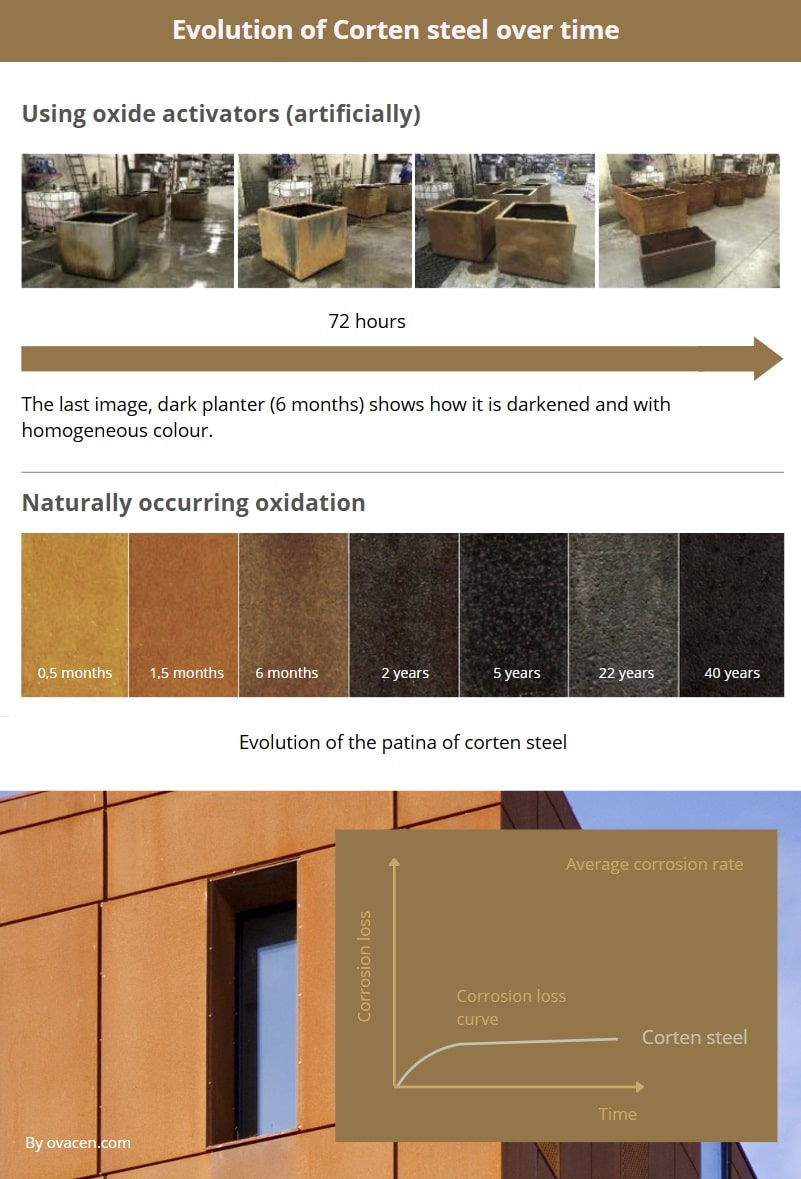

Over time, the development of the patina on corten steel is unique, and at this point, we need to break it down to understand what happens. First, let’s clarify some terms:

- Weathering steel: While commonly used as a synonym, it actually refers to the material’s ability to form a protective oxide layer that shields it from corrosion.

- Patina: Refers to the unique appearance of rusted steel, which changes over time.

The beauty of a patinated surface lies in its ability to change and evolve over time.

The factors affecting the patina that develops on the metal – influencing its color – will be faster or slower depending primarily on:

- Local weather conditions: Humidity, rain, temperature, and sun exposure can accelerate or slow down the process.

- Air pollutants: Pollution levels, such as sulfur dioxide (SO2) and chloride concentrations, can affect the speed and final appearance.

- Geographic location: Urban and industrial areas tend to see faster patina formation than rural areas.

From this point, its characteristic protective oxide layer develops in a minimum of two months with artificial activators. Without these additives, natural oxidation takes 2 to 4 years to complete.

The material stabilizes within the first 4 to 6 years. Between 8 and 10 years, the oxidation process becomes very slow and visually negligible.

? Note: When the process is artificially accelerated, it is not an exact science, and issues with oxidation may arise, such as scaling, dust detachment, etc.

Color appearance of corten

| Color | Condition |

|---|---|

| Orange-yellow | Initial stage of exposure |

| Light brown | Early stage of exposure |

| Chocolate brown to purple | Development of protective oxide |

| Black | Non-protective oxide |

The shade of the rust color changes depending on the intensity of oxidation (strong or weak), darkening to a deep orange-brown in aggressive environments or over time.

Maintenance of corten steel

Here, you should consider the following points for the care and maintenance of weathering steel:

- Although this type of material generally does not require protection or coating, protecting it with a high-quality anti-corrosion primer is highly recommended! For example, in planters, it prevents stains:

- In areas that come into contact with other materials or are embedded, use a primer (similar to those used for carbon steels). It should be applied up to about 10 cm above the embedded part to prevent capillary moisture.

- The corten finish requires almost no maintenance, but it is still essential to inspect and verify that everything is in good condition and clean off any dirt.

- Avoid using any detergents or brushing the surface; instead, clean it only with a soft cloth and water.

- If areas with chipping, scaling, or heavy corrosion appear, brush them off and apply specific products to reactivate the oxide (ask at a store).

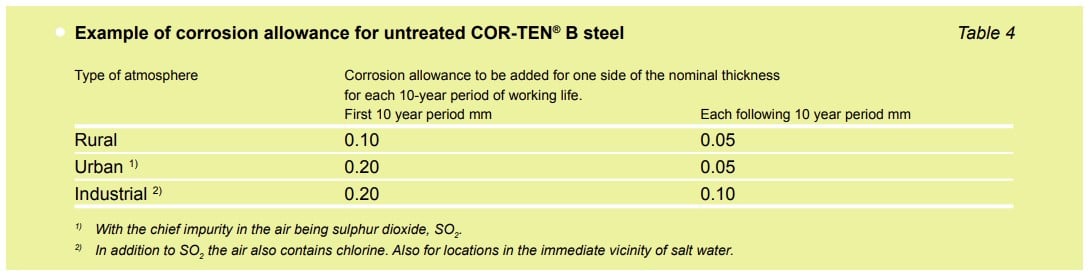

⚠️ Advice: In urban and industrial environments, the air contains sulfur dioxide (SO₂) and chlorides, which increase the corrosion of corten steel sheets. Therefore, an additional thickness should be considered to compensate for corrosion during its service life.

? Note: You can consult more technical characteristics of corten steel from HERE (pdf).

This final point should be considered by the professional and the corresponding supplier company depending on the use cases. It is important!

Now, we are interested in understanding how it is used in architecture and what we should consider. Pay attention!…

Architecture with corten steel

Although it may not seem so, many buildings and houses have used corten on facades to beautify them in different ways. Visually, it is an incredible material!

However, when using corten steel in architecture, several details must be considered in the projects… What should we look at when using this finish in architectural projects?

- Panel thickness: Thickness loss due to corrosion must be compensated by increasing the material thickness.

- Beware of accumulated water: Proper design and management of runoff water – gutters and pipes – is required to prevent staining. Allow rainwater to flow without retention.

- Storage: It is better to store the material in enclosed environments and avoid patios or open spaces.

- Patina formation: It cannot form if the steel surface is continuously wet or dirty.

- Exterior sheets: A primer should be applied – as with other common steels – to protect and prevent stains.

- In structure: Consider the weight imposed on the building structure.

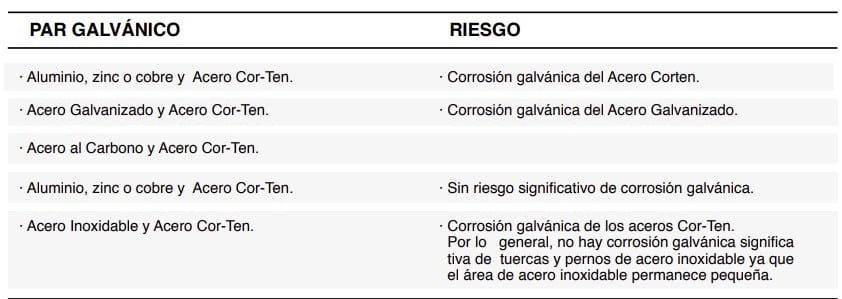

- Avoid galvanic corrosion: This occurs when two metals with different electrochemical potentials come into contact in the presence of an electrolyte. Use nylon spacers between materials.

? Note: You can consult more technical characteristics of corten steel from HERE (pdf in Spanish).

- Clean plates and laminates: If the layer of scales and dirt is not cleaned and removed, the patina may form unevenly, resulting in a non-uniform color, and the scales may detach.

- Avoid contact with other materials: As with other metals, keep it away from mud, grease, oil, paint, concrete, mortar, and other substances. Avoid direct contact with the ground!

| Materials easy to clean against corten | Materials difficult to clean against corten |

|---|---|

| Semi-matte or glossy enamel coating | Concrete and mortar |

| Anodized or simple aluminum | Hot-dip galvanized steel without paint |

| Stainless steel | Unglazed brick |

| Neoprene | Matte enamel |

| Ceramic tiles and glazed tiles | Stone |

| Glass | Wood |

- Use outdoors and in changing weather conditions: The protective layer cannot form uniformly in constantly dry or wet weather conditions, which is why many professionals do not recommend it for interiors.

- Avoid salt-rich environments: It should not be located very close to salty environments. It is recommended to maintain a minimum distance of 200 meters from the coastline.

Although it may seem like there are disadvantages to using corten steel in architecture, in reality, there are many more advantages in terms of durability, outdoor resistance, maintenance, and aesthetics.

Now that we know a bit more about when we can use it and what precautions to take… What architectural examples do we have?

Examples with rusted steel

The CaixaForum building in Madrid, designed by architects Herzog & de Meuron, features an impressive corten steel facade paired with an urban vertical garden.

This cultural building combines history and modernity, using this construction material to create a visual contrast with the surrounding buildings.

Another significant cultural building is the Centre Pompidou-Metz (Metz, France), designed by Shigeru Ban and Jean de Meire, featuring a unique roof supported by a facade of self-weathering rusted steel tubes and beams that interweave to create a lightweight and transparent structure.

Designed by Feilden Clegg Bradley Studios, we have a building fully clad in corten. Broadcasting Place surprises us with its facades near the city center of Leeds, England.

We shouldn’t just talk about this sustainable material covering large walls. In modern homes, it is also applied in many forms.

For example, Casa CS (Casa Corten) by the architectural studio of Antonio Altarriba. Located in a residential area of Bétera, Valencia, this material has been used to enhance its exterior design dramatically.

Minimalist carpentry has been provided by Dekovent, featuring brass, corten, or stainless steel doors and windows that are stunning, certainly luxurious and unique products. An example:

Of course, we can also see many examples of urban furniture with this protective oxide layer. Just look around – cities are full of them!

In the Guggenheim Museum Bilbao, designed by Frank Gehry, there is an impressive example of using corten-textured steel in art. The permanent exhibit by Richard Serra, titled “The Matter of Time,” showcases the strength of this material.

Reference points and useful documents:

- PDF Corten Steel by Innometal. Available at https://www.imar-innometal.com/es/descargas

- From Wikipedia at https://es.wikipedia.org/wiki/Acero_corten

- PDF by Assagal. Access at http://www.agasasl.com/fichas/714-ficha.pdf

- Thesis on Weathering Steels (Cu, Cr, Ni). Available at https://docta.ucm.es/entities/publication/e0bc1f53-4c38-436a-9ca6-6424f25ce8a2

- PDF European design guide for the use of weathering steel. Available at https://www.steelconstruct.com/wp-content/uploads/ECCS-Design-Guide-Weathering-Steel-Bridges.pdf

- PDF by Ruukki – Weather resistant structural steels EN10025-5 and COR-TEN. Available at https://infantas.lt/wp-content/uploads/2019/04/COR-TEN_HR_08.2008_EN.pdf

- PDF Weathering Steel Structures Inspection and Maintenance Suggestions. Available at https://az276020.vo.msecnd.net/valmontproduction/docs/librariesprovider91/white-papers/weathering-steel-structure-maintenance.pdf

If you enjoyed this article, share it!