Robotics that move buildings

We had already seen a house or even a small building moved in one piece, but relocating a complete 7,500-ton historical complex is a whole different story!

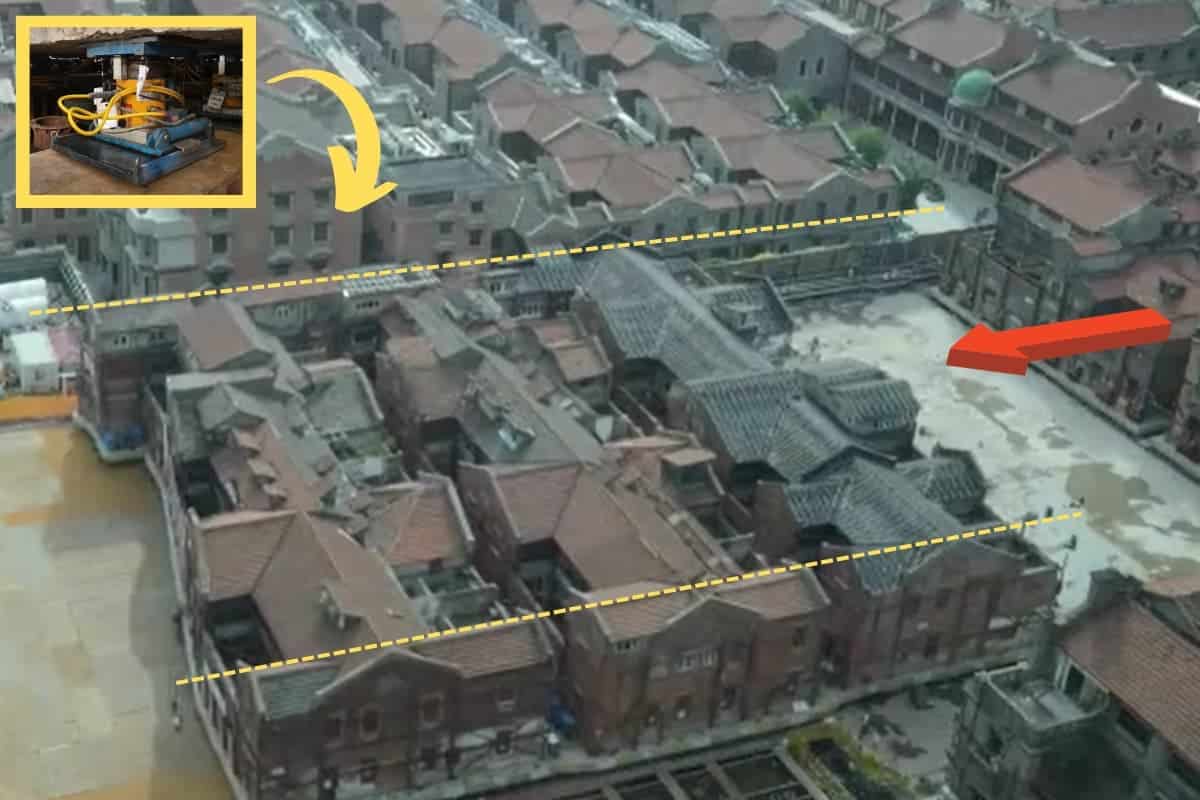

Well, it happened in the wonderful city of Shanghai, and all thanks to an army of 432 robots under the base of the Huayanli building complex that moves 10 meters a day.

The goal! to make way for a three-level underground megacenter with an area of more than 53,000 square meters, which will house cultural areas, shops, metro line connections, and many parking spaces.

All this in the heart of the legendary Zhangyuan neighborhood, in an area with more than 140 years of history with a dense distribution of historical structures.

The Huayanli complex, composed of three historical shikumen style buildings (a unique urban architecture of Shanghai) built between the 1920s and 1930s, weighs a total of 7,500 tons, and has an area of 4,030 square meters.

The robots not only lift and hold the structure, they literally “walk” with the building, adapting to the narrow and fragile environment of the old neighborhood. The operation is considered the largest ever carried out in China in terms of weight, size, and complexity.

“Walking Machine” robotic system. Technology that allows robots to move as if they were walking, ideal for narrow spaces

The relocation of the complex is temporary: once the underground works are completed, the buildings will be returned exactly to their original location, as if they had never been moved

The density of the Zhangyuan neighborhood – with its narrow streets and historical buildings very close to each other – made any traditional method of demolition or reconstruction unfeasible. The engineers had to use the latest in robotics to move the entire building complex.

Movement system

- Number of robots: 432 units

- System type: Modular robotic platform with omnidirectional movement capability

- Key technology: “Walking robot” system, inspired by human movement to adapt to uneven terrain and tight spaces.

Specifications per robot

- Load capacity per unit: Up to 10 tons

- Adjustable height: Allows lifting structures from the ground to a certain height for maneuvering

- Controlled direction: 360° turns, lateral and diagonal movements

- Average speed: 10 meters per day (approximately 0.4 m/hour)

- Centralized control: Synchronized operation through real-time monitoring software

System operation

- The robots are placed under the previously reinforced building.

- The structure is elevated in a controlled and coordinated manner.

- Each robot has sensors that monitor: Pressure, unevenness, vibrations, and all with very precise calculations.

- With artificial intelligence, the system automatically adjusts the balance to avoid damage to the structure.

As a result, the impact on the area has been minimized to the maximum, allowing modern development to advance without sacrificing the historical legacy.

The key to success also lies in AI, which allowed the machines to distinguish between clay and obstacles. The engineers used BIM modeling and point cloud scanning to create detailed 3D models.

These models facilitated risk identification, precise route planning, and the design of curved trajectories for the land. A conveyor belt system, similar to a production line, ensured an efficient path with minimal interruptions.

China has a long and amazing history of moving large structures. In fact, it is not the first time that the Asian country has amazed us with the movement of entire buildings.

And there is also the relocation of the Jade Buddha Temple in Shanghai, which was moved 30.6 meters, or the Hankou Yiyong Fire Association building, which slid 90 meters on rails.

If you liked the article, share it!