Concrete prefabricated housing

An alternative to traditional construction is concrete prefabricated houses. These constructions use modular technology from the factory to achieve better finishes and fast assembly times.

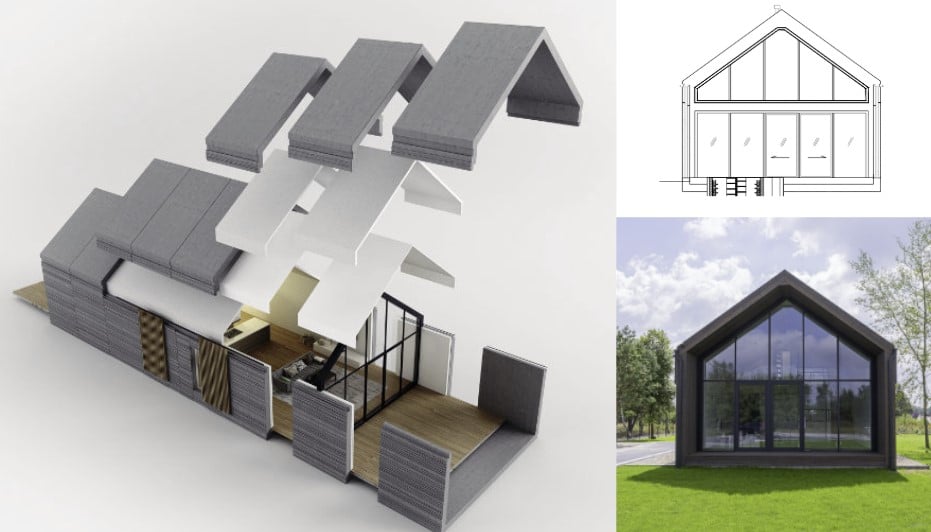

Prefabricated houses – for the most part – use flat roofs assembled on site. What if we incorporate a gable roof into the concrete prefab itself?

This concept is proposed by the innovative company Spine Domy – all in one! The prefabricated module consists of two components; floor and walls, plus a gable roof directly forming the structure of the house.

This new construction system further simplifies the construction of prefabricated houses with a design that promotes better quality

Possible problems caused by flat roofs directly disappear, and at the same time, being two modules that form the structure set, it’s all advantages!

Imagine! The on-site execution to assemble the entire structure of the concrete modular house is super fast, around a day for one of 100 m2!

Of course, the final design of the house does matter, and with this new construction system, the aesthetic standard of the prefabricated house that we are used to seeing in the market is broken.

Now, you can have considerable height in your living room with large windows, all with a prefabricated house

Due to the construction system, the interior of the house can be adapted to the needs of each owner, being not as rigid as the standard prefab or container houses.

Obviously, due to its modular design and aesthetics, there are also restrictions on the final result of the house, although the combination of prefabs can vary quite a bit.

In their catalog that you can see from HERE at Spine (It’s in Polish), the smallest house they offer is almost 50 m2 built, then we move to 88 m2, 100 m2, etc. As a note, there are L-shaped designs, double modules, etc.

It seems that the houses are currently delivered in a “raw” state, that is, not completely finished:

- Factory construction and structure assembly.

- Carpentry that includes the windows.

- And the roof cladding.

It is important to note that the houses are not delivered completely finished. As they comment, the limitation is due to the difficulty of supervising the work due to the geographical dispersion of all locations.

In the company’s videos, they comment that the manufacture of a 100 square meter house is achieved in a period of one week (give it 2 to 3 months and this being fast), with a maximum of 10 days as the upper limit.

The speed of manufacturing is due to the company seeking to prefabricate as many elements as possible in the factory, so that only assembly is required at the construction site.

We find it a different solution to what we normally find in prefabricated houses on the market, with a quite interesting construction solution in the roof, not to mention that the floor and walls are a single modular unit – much fewer headaches on site and future problems!

What do you think of the project? Would you find it interesting to build a house of this type? We have asked for prices – via email – and have not yet received a response. If we find out anything, we will share it.

If you liked the article, share it!