The startup queen of exposed brick facades

There are as many ways to build and design exposed brick facades as you can imagine; making the masonry look good, be lightweight, and cheap to build is another matter.

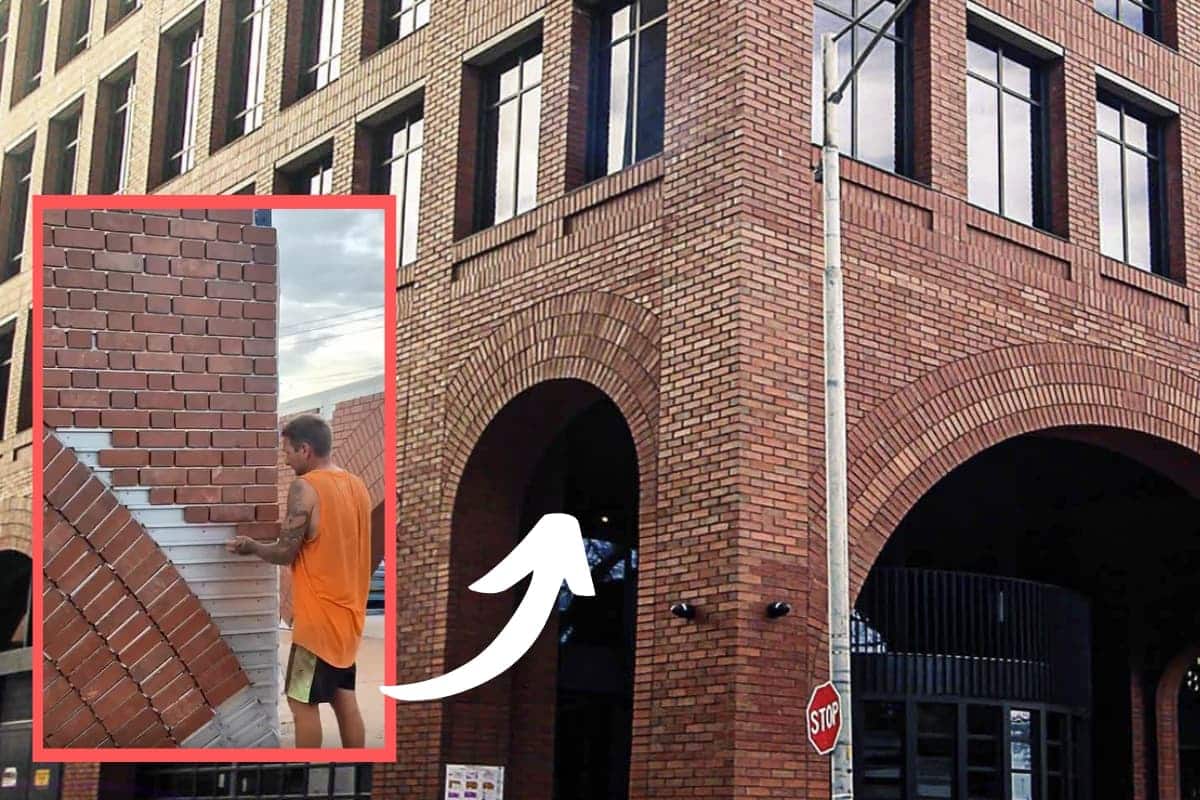

And if we add that we want arches and curves in our building, this gets more complicated! The solution to these headaches comes from the Australian startup Modular Masonry Group, with its star product NexBrick.

The idea is simple… Do you want an exposed brick facade that’s impossible to build? Well, they produce it directly in the factory – even if it has a thousand curves – and then the panels are assembled on site or wherever you want, just like that!

The interesting thing about this startup is not the modular masonry – which already exists – but the possibility of building unthinkable facades with almost perfect finishes

The company offers a comprehensive, lightweight, and most crucially, flexible facade system! Perfect for creating complex architectural designs, including large arches and curved surfaces in buildings.

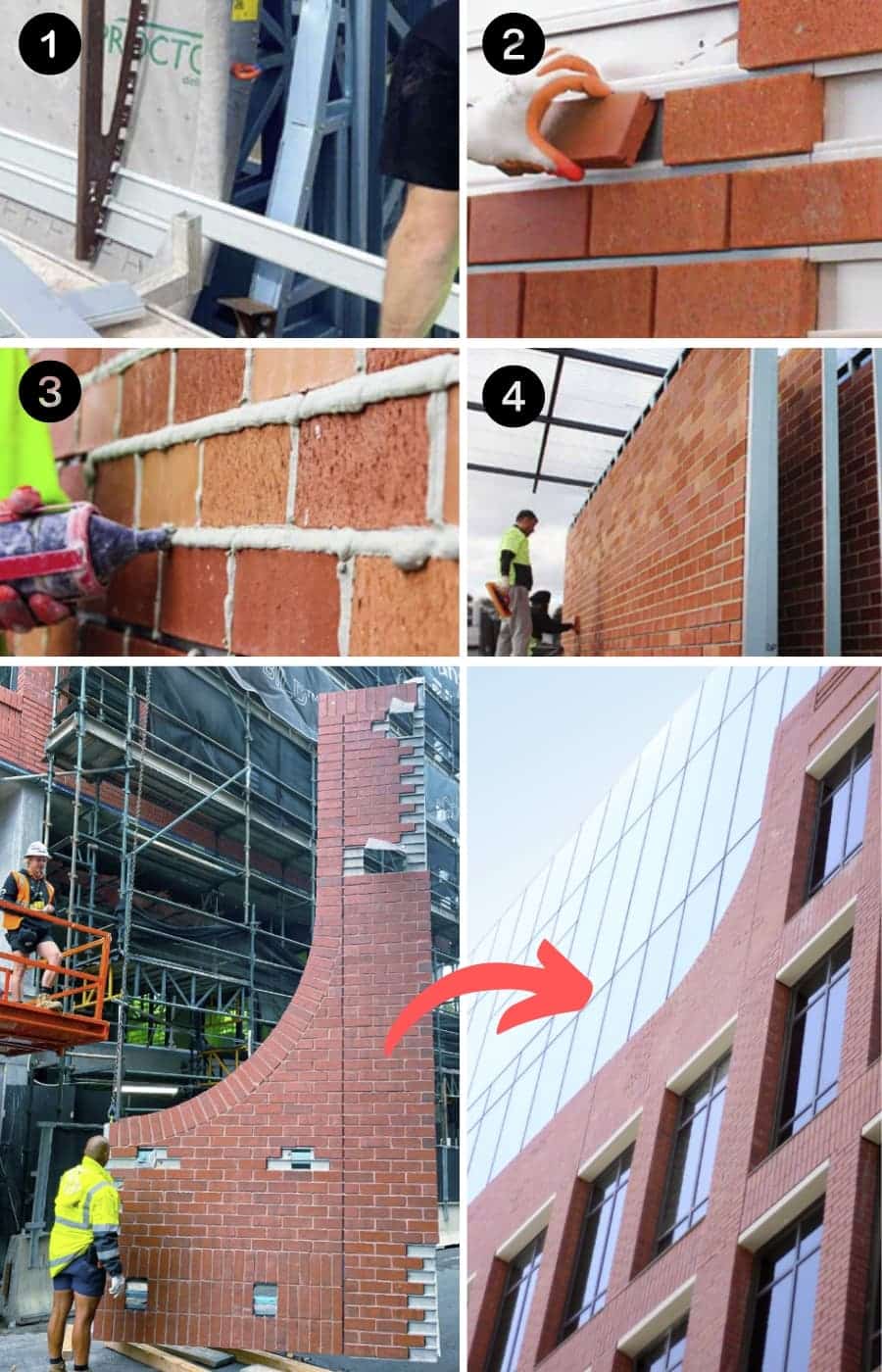

How does it work? The NexBrick modular masonry system consists of four main steps:

- – Mechanical fixation: The system uses lightweight exposed brick units (bricks of only 55 kg per m²) that are installed dry, without the need for mortar.

- – Support rails: Installation is done by attaching the brick units to metal channels that extend horizontally over a base wall.

- – Brick sealing: Once all the bricks are fitted into the structure, the joints are sealed with the appropriate mortar.

- – On-site assembly: The finished lightweight panels are delivered to the relevant construction site and assembled like a “lego” forming the building’s exterior facade.

With this prefabricated system, the material can adapt to sinuous shapes with ease and efficiency never seen before

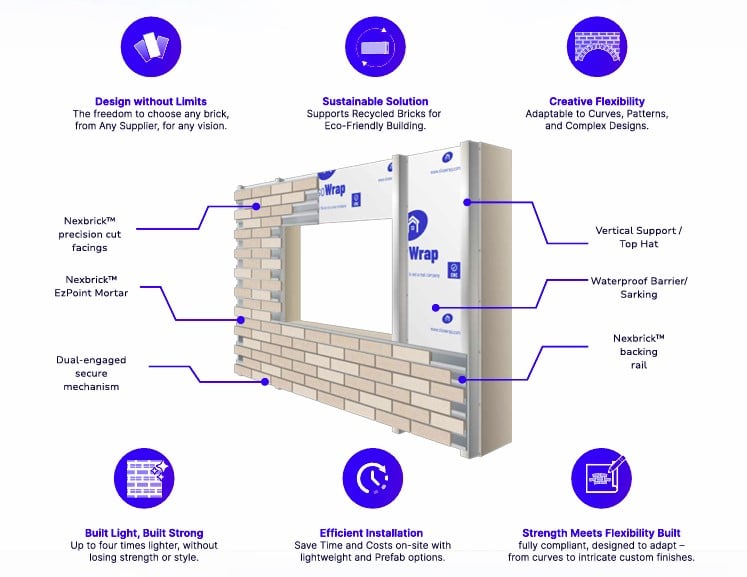

The result of this transformation is a bold proposal: combining the durability, aesthetics, and authenticity of traditional brick with the efficiency, lightness, and flexibility that modular construction allows for house facades or buildings.

This system allows for tangible advantages over the incorporation of curves in the design of exterior brick facades which has traditionally been a costly process, and also:

- The modularity ensures controlled aesthetics even in complex works developed in tight deadlines.

- The system allows for ceramic facades with lightweight panels that speed up assemblies in architectural projects.

- The modules reduce time both in execution and in their assembly on site.

- The processes incorporate methodologies inspired by CAD to coordinate design and execution simultaneously.

- The pieces maintain authentic texture through precise controls that preserve the original traditional aesthetics.

- Waste is reduced by precisely controlling all materials.

- Possibility of producing exposed brick facades with unthinkable patterns and geometries.

If you are curious to know more about the construction system of the company Modular Masonry Group you can see the official catalog from HERE (PDF on DropBox).

We find it a paradigm shift: from heavy to agile, from rigid to flexible, where the designer or architect gains enormous creative freedom with possibilities to design viable and economically accessible masonry facades or constructions.