Robotic microfactories to build prefabricated wooden houses

What if I told you that you can start a company to manufacture fully robotic wooden houses in three months. And everything is calculated for mass production: design, costs, assembly, from the first cut to the last screw.

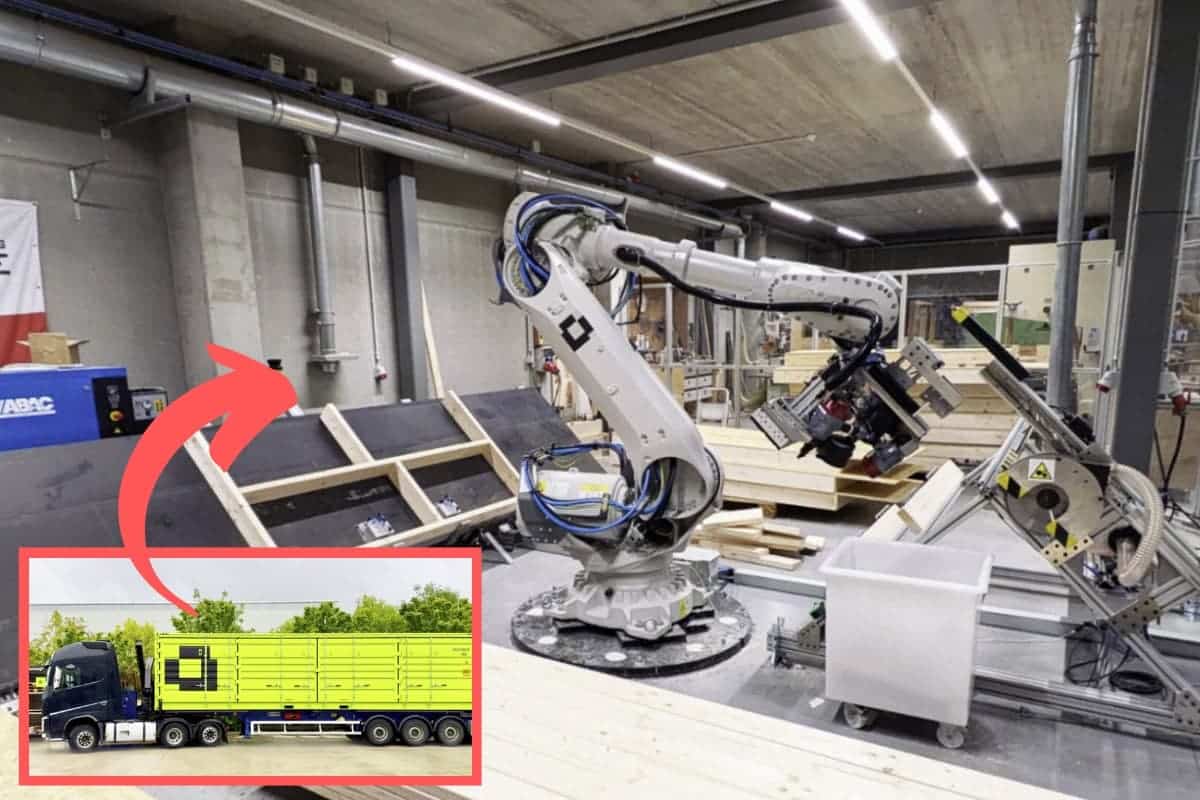

This idea is not fiction; it is what the startup AUAR (Automated Architecture) proposes. They deliver “robotic microfactories” that are easy to deploy – plus software – so you can start assembling with robots the walls, floor, and roof of prefabricated houses just like that!

Comprehensive automation with robotics to design and deliver quality homes, achieving a total cost reduction of between 30% and 40%.

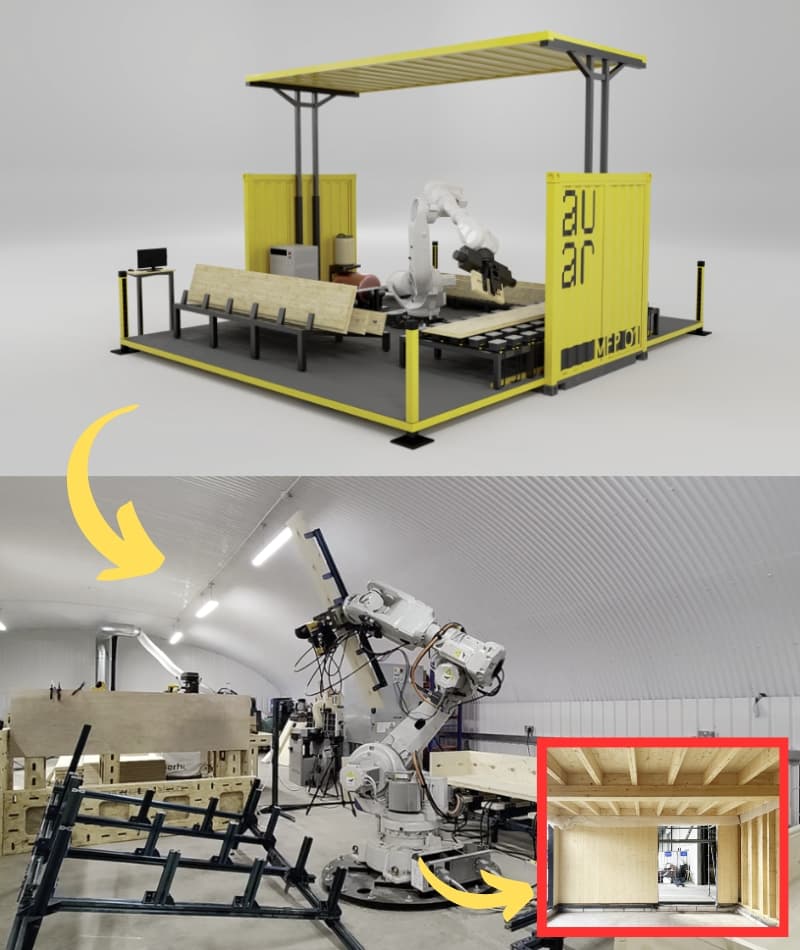

The “microfactory” technology is the heart of the proposal. A robotic cell that receives standard wood panels, cuts them, assembles them, and delivers structural components to be assembled.

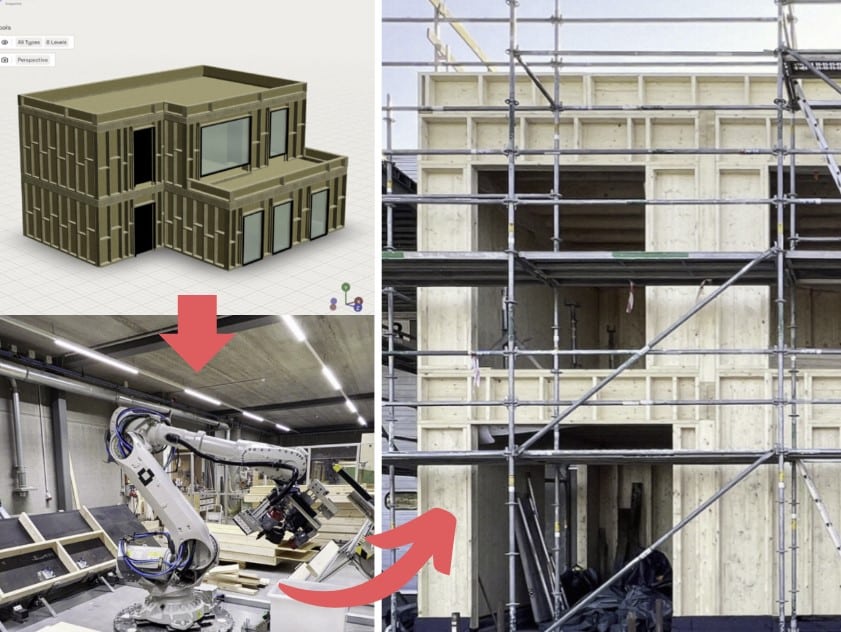

The majority of the work is already prefabricated with precision for construction. Everything is calculated, even the assembly sequence. When the team arrives at the site, they assemble “like a lego,” and that’s it.

Instead of trying to fit robots into a classic construction site, they thought of houses as prefabricated modules. Where the architectural design must already accommodate what machines can cut, assemble, or transport.

The workflow proposed by the innovative company would be as follows:

🟧 Note: In the same line of robotics, you can see the automatic tile laying machine.

The startup seeks to solve the housing shortage by accelerating production and agility:

- Distributed and agile model: Unlike large modular factories that require a continuous and standardized production line, the system allows the deployment of robotic microfactories that can be located in small facilities or even directly on construction sites.

- High production capacity: A single microfactory is capable of producing the floors, walls, roofs, and coverings for 120 homes per year. It can even produce a house in a day.

- Adaptability and localization: A flexible and adaptable wooden frame construction system is offered to accommodate any design constraints. It allows localization and adaptation to local planning and design requirements, something that large prefabricated housing factories cannot execute.

- Adaptable to construction typology: Single-family homes and small buildings of one to three floors (four floors in the U.S.) can be created, and work is underway to offer medium-height structures of six to eight floors.

The bet of this construction-related startup was to rethink construction from the origin: redesign the pieces, workflows, and materials so that automation is not an “addition” but something integrated.

This model does not depend so much on highly specialized labor because most of the process is transferred to the factory. Less waste and more quality control: in each module, you can check for faults before they reach the site.

It also addresses social sustainability issues and CO2 emissions in construction:

- The wooden frame solution achieves more than 40% less CO2 than EU targets.

- Each house built is essentially a carbon sink, capturing 12 metric tons of CO2 just in the wooden frame (Interesting to see new construction materials)

- The microfactory adapts its program in real-time to cut pieces and store leftover material, resulting in minimal material waste (around 1% in total).

- The platform is designed to meet the Passive House standard in its baseline. The software is adapted for EU and U.S. building codes.

But… What about investment costs or benefits? As we can see in the initial video, the cost of manufacturing the wooden frame panel is reduced by up to 70%. And for handling, it requires only one operator for < 2 hours/shift.

The delivery from when the customer places an order for a microfactory until it is received and ready for production is about 12 weeks.

Regarding expenses: there is an installation fee, a rental fee for support and remote operation of the microfactory, and a variable usage fee per square meter. Although this may seem hefty, its approximate return is “270 pounds of profit” for every pound spent.

If you want to know more about the company AUAR (Automated Architecture) you can enter HERE on their official page.

There will be trials, there will be failures, but the project is not utopian: it is operational, with real houses already built, real materials, real processes. We will see if in a few years those microfactories will be installed in our country and building homes that surpass the traditional model.

If you want to learn more about robotics, you can check out the following humanoid household robot that are crazy with very advanced technology.

If you liked the article, rate and share!