3D printed housing with earth

There is a lot of talk about prefabricated houses and their sustainable construction, but little about the potential of 3D printing houses. And we will have to change our thinking because we can already build them with earth.

The Japanese architecture studio Lib Work has revolutionized the sector with a 3D printed house made of earth. Its design is spectacular, and best of all, its environmental impact is minimal.

The 3D printer uses a natural mixture of lime, plant fibers, and local soil to mold the walls, layer by layer, instead of traditional concrete. The house seems like an extension of the land.

This new material not only redefines construction but also transforms our relationship with the environment. It offers a real, solid, and conscious alternative, marking the beginning of a new sustainable architecture.

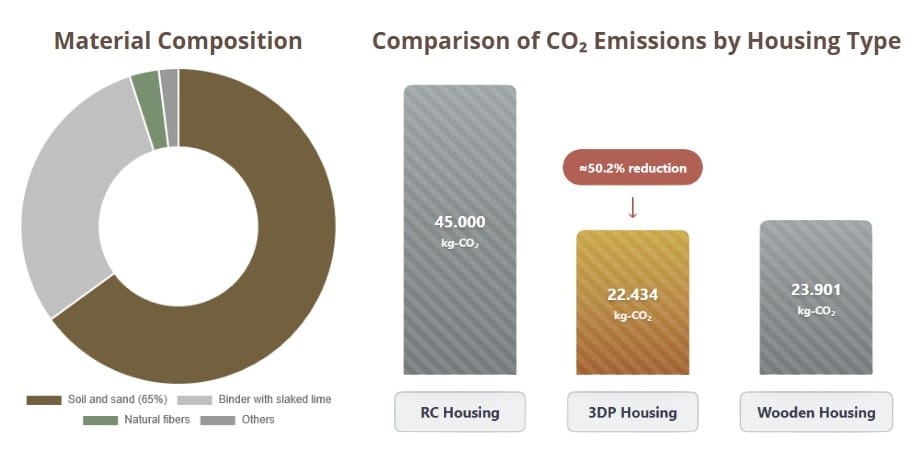

According to the architecture studio… “By eliminating cement from a 100 m² house, CO₂ emissions are reduced by up to 50% compared to reinforced concrete and even surpass wood.”

The star component is, of course, the earth, but not just any way. To create a strong and durable mixture, it is combined with other natural building materials in a patented formula, based on clay, sand, fibers, and a natural binder like lime.

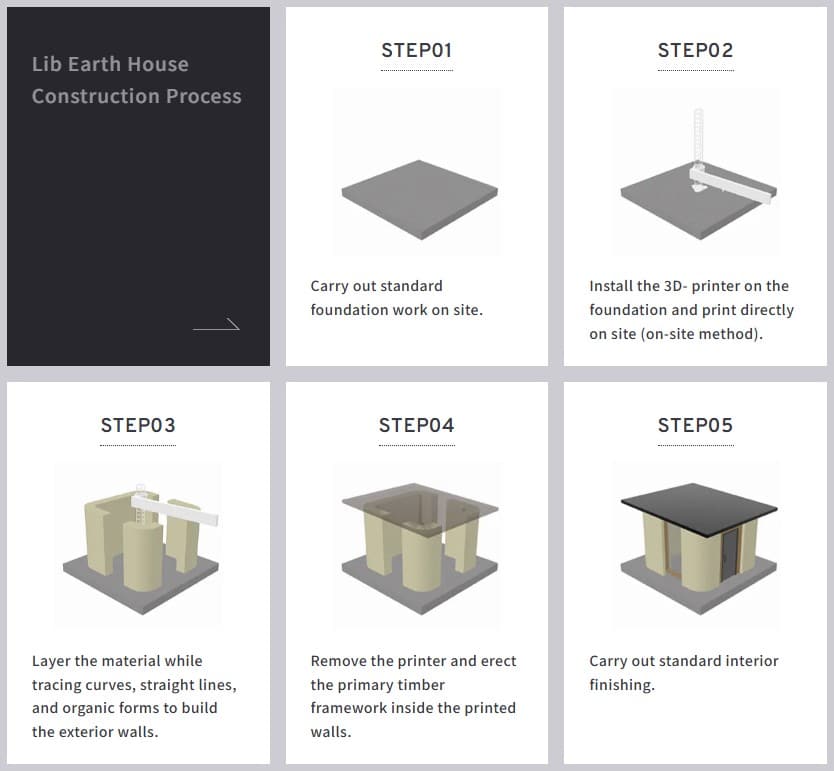

The construction process is simple but highly technical, a giant robotic arm deposits a mixture of earth following a digital plan with millimetric accuracy. The walls of the house grow and solidify, creating a robust structure.

If you think the structure is weak because it doesn’t contain concrete. It reaches seismic grade 3, meeting Japan’s strict standards

This method is incredibly fast and efficient, drastically reducing construction times and minimizing waste thanks to its precision. It is, in essence, a form of sustainable and smart construction that is destined to gain prominence in the coming years.

The benefits of these 3D printed houses with earth are immense. They represent a greener and more accessible future! The transformation of the traditional home concept is total.

- Deep sustainability: They use local and natural materials. The carbon footprint is minimal compared to concrete.

- Design freedom: They allow for organic shapes and curves. Designs that were once impossible are now a reality.

- Construction speed: Printing accelerates the times. Reduces the wait to have your new home.

- Cost reduction: Less labor and material. A more affordable home.

“We build more than houses; we sculpt shelters that breathe in harmony with the planet, using the earth you walk on”

Additionally, the energy efficiency in construction is remarkable. The earth walls offer superior thermal and acoustic insulation, maintaining constant interior comfort.

With 3D housing printing, the limitations of rectilinear shapes disappear. Earth buildings flow, integrate with the landscape in an organic way, and allow for creative freedom that was previously unthinkable for architects.

Each design can be perfectly adapted to the climate and topography of the place, making the house not only belong to the owner but also to the landscape.

The other good news is that we are not talking about a housing prototype. The Lib Work studio wants to internationalize the 3D manufacturing process with earth through franchises. Also of interest is the article on container house architecture. A good guide!

[ai_summary_buttons]

If you liked the article, share it!